Laser engraving aluminum, also known as laser marking or laser etching, entails the creation of graphics and patterns on aluminum surfaces using laser beams.

In this comprehensive guide, you'll explore all aspects of aluminum laser engraving, including its definition, suitable aluminum materials, and detailed steps for laser engraving aluminum.

In this article:

Part 1: Introduction of Aluminum Laser Engraving and the Machine

Aluminum Laser Engraving Explained:

"Can you engrave aluminum with a laser?" Absolutely! Aluminum laser engraving works by directing a focused laser beam onto the surface of aluminum, which causes localized heating and vaporization of the material. This process removes a thin layer of aluminum and creates the desired engraving, such as text, graphics, or patterns and this method offers precision and versatility.

Different scenarios call for different types of lasers. Three commonly used for laser engraving aluminum include:

- CO2 Laser: Uses a carbon dioxide gas mixture to generate the laser beam. Offers high precision and flexibility, making it well-suited for aluminum engraving.

- Diode Laser: Uses semiconductor diodes as the laser source. Compact, efficient, and suitable for aluminum engraving, especially for smaller applications.

- Fiber Laser: Utilizes optical fibers to amplify the laser beam. Highly efficient and capable of producing high-quality engraving results on aluminum, making it a popular choice for industrial applications.

So, What is the best laser for marking aluminum? Actually, Each laser type - CO2, diode, and fiber - presents distinct advantages tailored to specific aluminum engraving requirements. For example, If you're looking to create personalized and small aluminum items as a DIY project, we recommend using a diode laser engraver due to its cost-efficiency and portability.

The Machine You Need:

To embark on aluminum laser engraving, you'll need a laser engraving machine specifically designed to work with aluminum materials. Among these laser engraving machines, a diode laser engraver is suitable for small to medium projects, while CO2 and fiber lasers are ideal for larger or industrial-scale projects.

Part 2: What Types of Aluminum Materials Can Be Lasered?

Various types of aluminum materials can be laser engraved. Here are three commonly used types:

- Bare Aluminum: Untreated aluminum surfaces can be directly engraved using laser technology, creating precise designs and markings.

- Anodized Aluminum: Anodized aluminum features a protective oxide layer that enhances its durability and provides a smooth surface for laser engraving. The laser removes the anodized layer to reveal the underlying aluminum, resulting in high-contrast markings.

- Powder Coated Aluminum: Powder-coated aluminum surfaces are coated with a layer of powdered paint, which is then cured to form a durable finish. Laser engraving can remove the powder coating to reveal the bare aluminum underneath, allowing for detailed and customizable markings.

Bare aluminum and anodized aluminum can be effectively laser engraved using CO2, diode and fiber lasers, while CO2 and fiber lasers are the best choices for engraving powder-coated aluminum.

All in all, each type of aluminum material offers unique characteristics and engraving results, making it essential to choose the most suitable material based on the desired outcome and application requirements

Part 3: Laser Engrave Aluminum Card within 5 Detailed Steps

Aluminum laser engraving lets you add personalized and intricate designs to your Aluminum-made items. Whether it's patterns, sayings, or pictures you want to engrave, the process is simple. Just follow these 5 easy steps, and you'll get stunning laser engraved aluminum crafts.

Step 1: Choose Your Aluminum Material

Aluminum materials mentioned in Part 2 are all good choice for aluminum laser engraving. However, please remember that it's important to choose laser-safe aluminum material to avoid any potential safety hazards.

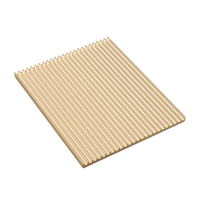

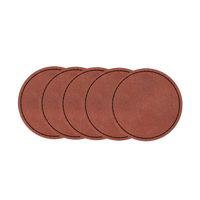

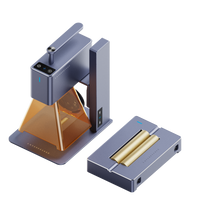

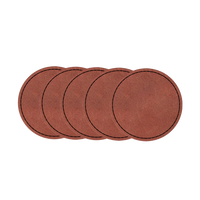

So, in this guide, we'll use aluminum alloy metal card for our laser engraving demonstration.

;)

Step 2: Choose the Right Laser Engraving Machine for Aluminum

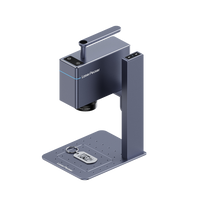

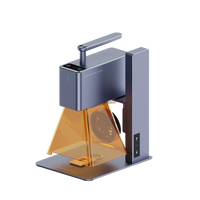

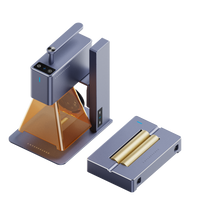

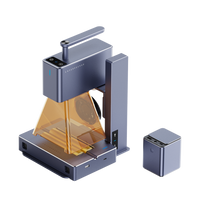

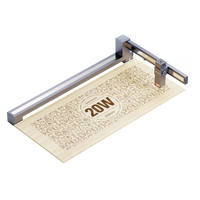

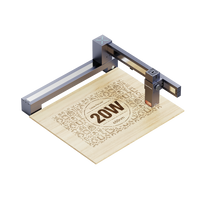

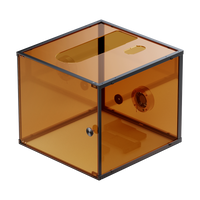

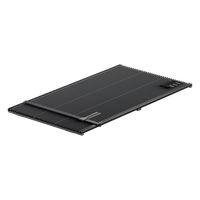

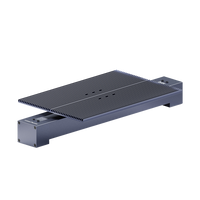

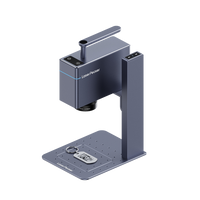

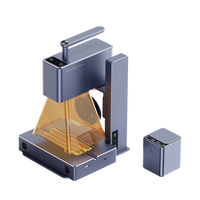

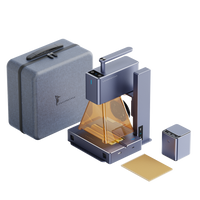

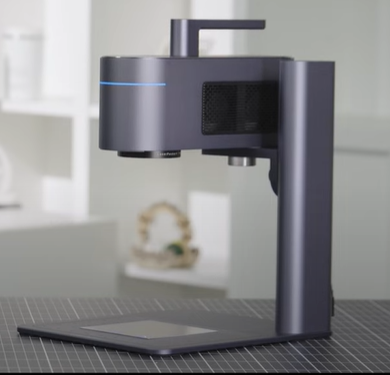

Here, we recommend LaserPecker 4 (LP4), which is a dual-laser and multi-functional laser engraver.

LaserPecker 4 (LP4) - A Good Engraver for Laser Aluminum Marking

Main Features of LaserPecker 4

- Dual-Laser Capability: The LP4 features dual lasers, providing flexibility to tailor your choices based on scene requirements.

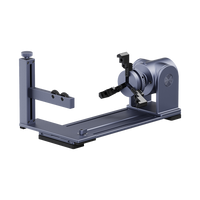

- Enhanced Material Compatibility: LP4 is compatible with a wide range of materials, including engraving aluminum, paper, bamboo, wood, titanium, silver, gold, copper, brass, silicone, rubber, crystal, stone, metal, leather, etc and cutting acrylic, leather.

- Improved Resolution: With selectable resolutions ranging from 1k to 8k, the LP4 provides increased flexibility, allowing users to choose the level of detail that best suits their needs..

- High Engraving Accuracy & Speed: The LP4 exhibits high engraving accuracy and speed, achieving precision levels up to 0.003 mm and speeds reaching up to 2000 mm/s.

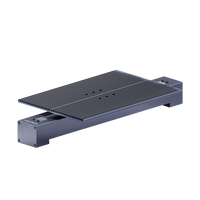

- Expanded Workspace: The LP4 provides an expanded workspace of up to 160 mm x 120 mm, enabling engraving on larger objects.

- Intuitive LED Touch Screen: The LP4 features a smart LED touch screen, enhancing your engraving experience with ease of use and smooth navigation.

Step 3: Prepare Your Engraving Design

Use graphic design software to create or import the image or pattern you want to engrave on the aluminum card. Consider size, shape, and details like text or patterns.

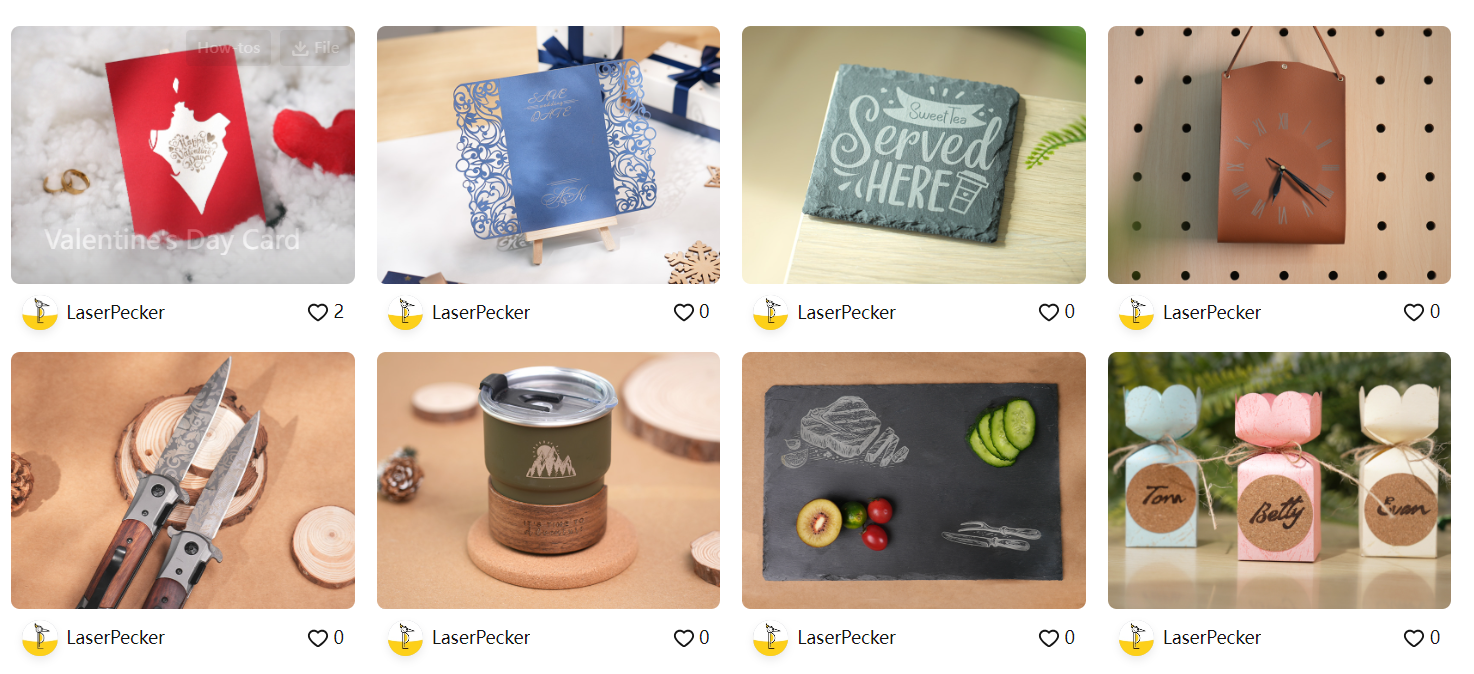

If you lack inspiration or ideas for laser engraving on different materials, visit our CraftZone for a wealth of laser marking design ideas and inspiration.

Step 4: Set up the Aluminum Laser Engraving Machine

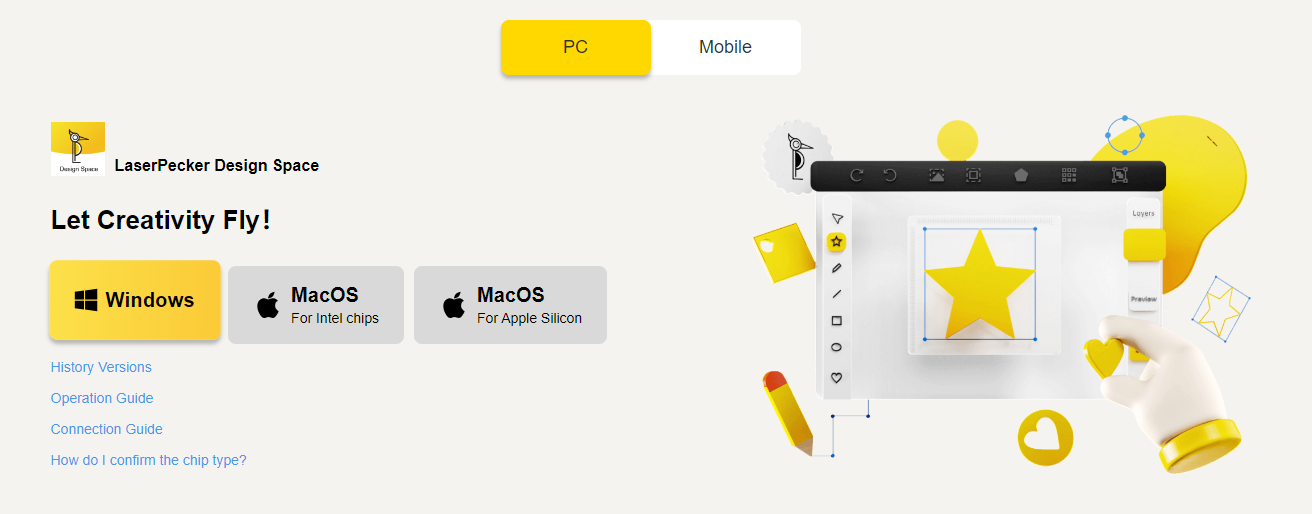

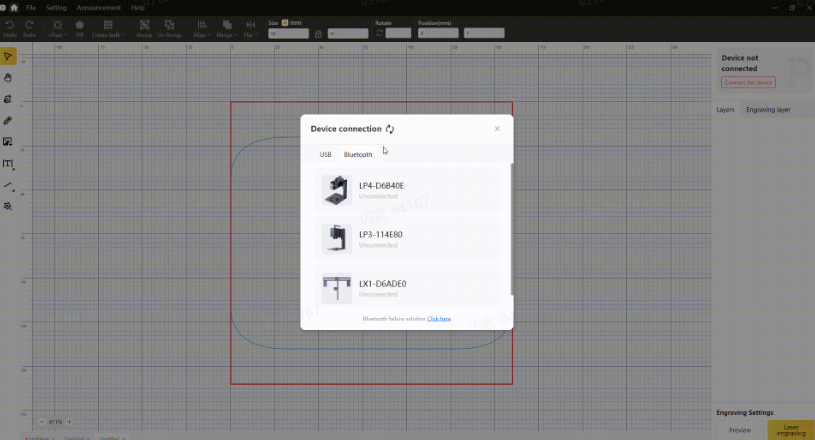

Firstly, Make sure your engraver is powered on, and then connect your laser engraver to your computer or mobile device using the appropriate interface (USB, Bluetooth, etc.)

Secondly, Open the graphic design software and load your design.

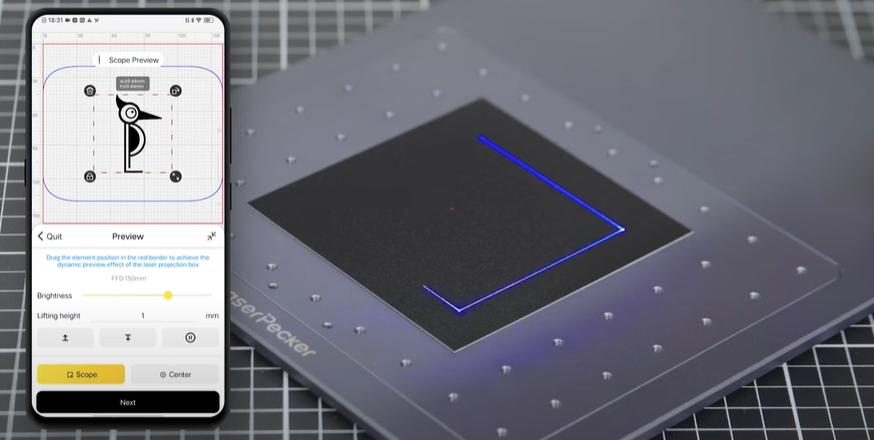

Thirdly, Turn on the "Preview Mode" to confirm if the laser lens is correctly focused. To verify it, you have 2 methods.

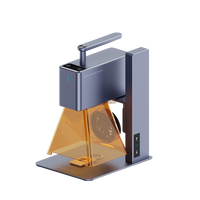

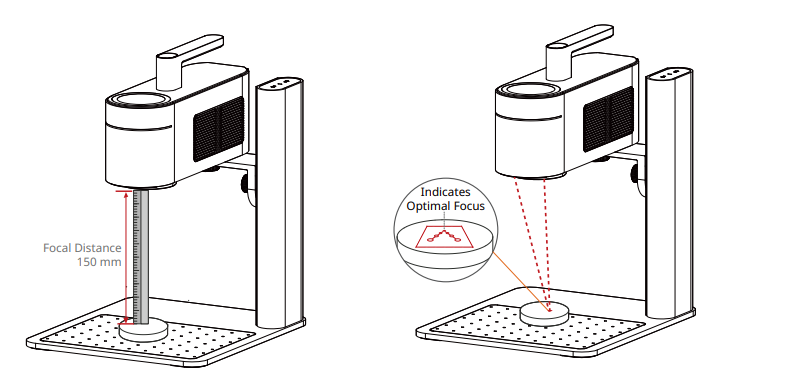

If you choose LaserPecker 4 (LP4), the first method is to use a ruler to measure the distance between the aluminum card surface and the machine, with a recommended distance of 15cm or 150mm.

Alternatively, you can achieve the correct focal length by judging whether the two red dots emitted by the machine overlap. This ensures precise focusing for optimal engraving results.

Fourthly, You need to place your aluminum-made items within the designated working area and examine the design's appearance on the aluminum card. If it doesn't fit correctly, you'll need to adjust its position and size to ensure it aligns with the dimensions of your project.

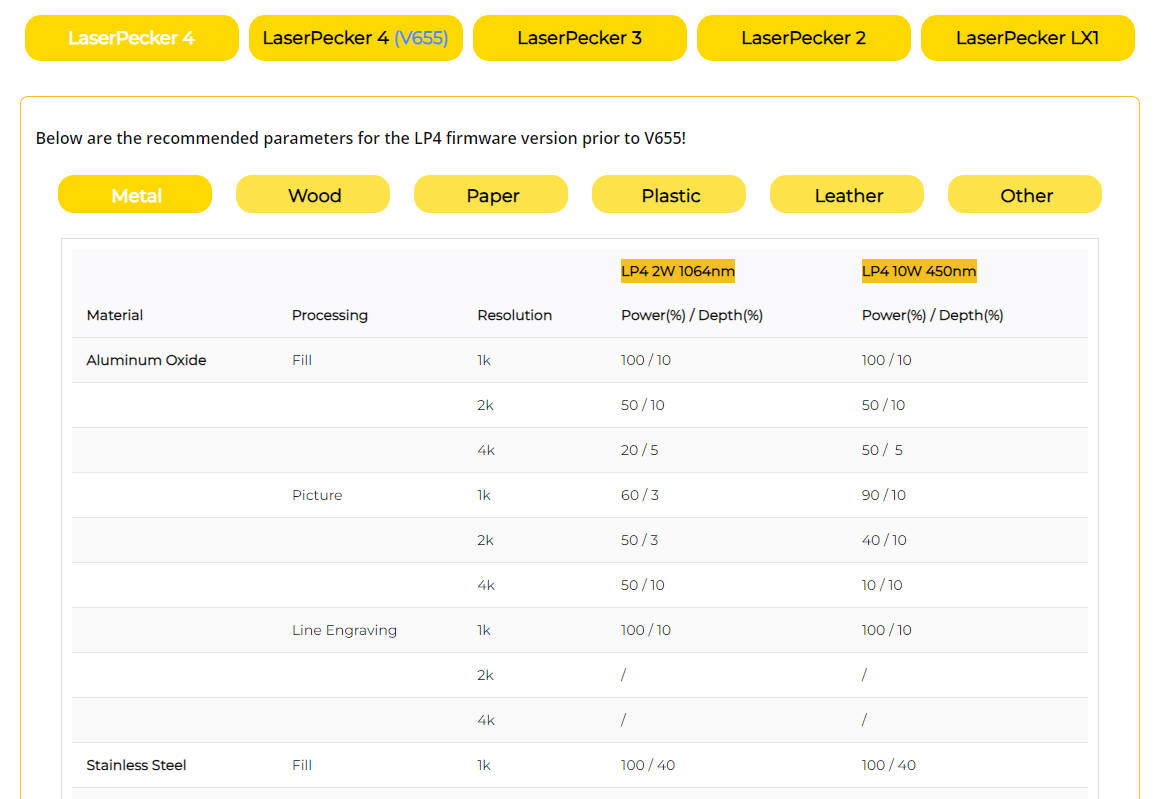

Finally, Access the software's laser settings to adjust parameters like power, speed, and resolution according to the aluminum card's properties and design intricacy. You might ask, "How much laser power is needed to engrave aluminum card?" and "How deep is the laser etch on aluminum card?

To get the best result, the recommended laserpecker 4 material settings for aluminum items is 1 W 1064 nm; Resolution: 2k; Power: 100%; Depth: 3%; Pass: 1

To explore other recommended laserpecker engraving and cutting parameters, refer to the settings table that applies to any laserpecker machines, including LP1, LP2, LP3, LP4 and LX1.

Step 5: Start Your Aluminum Engraving Now

Double-check everything to avoid mistakes. Then, hit the start button and watch the magic happen. The laser brings your design to life. Keep an eye on it, and you're all set!

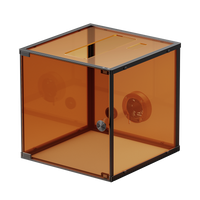

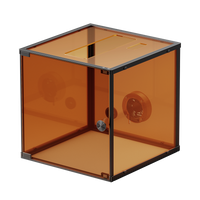

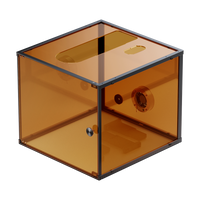

When operating a laser engraving machine with a 450 nm blue laser, it's advisable to wear goggles or use a laser protection cover to protect your eyes and body from potential harm, as the blue laser can pose risks.

Additionally, please be mindful that smoke or toxic gases may be emitted during the aluminum laser engraving process. Wearing a mask or employing an air purifier is essential for safety.

If you want to know more about how to use the LaserPecker LP4 machine, check out the LP4 User Manual on our website!

Conclusion

In short, this guide introduces aluminum laser engraving and its ability to transform personalized art. We hope it inspires you to explore aluminum laser engraving, allowing your creativity to flourish and bring imaginative designs to life on aluminum materials.