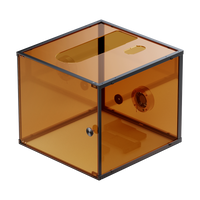

Acrylic, prized for its transparency, durability, and versatility, finds widespread use in daily life due to its lightweight build and resistance to shattering.

Acrylic laser cutting, also known as laser cutting acrylic, is a refined method for precisely shaping acrylic sheets into various designs, letters, or shapes. Cutting acrylic with laser, your creative ideas can be transformed into stunning crafts effortlessly.

In this guide, we'll delve into acrylic laser cutting, covering all aspects from beginning to end! Additionally, we'll include a case study on laser cutting acrylic sheets. Let's embark on this exciting journey together!

In this article:

- Part 1: What is Acrylic Laser Cutting?

- Case Study: Laser Cut Acrylic Sheet Within 5 Steps 🔥

Part 1: What is Acrylic Laser Cutting?

1. How Does Laser Cut Acrylic?

"Can you cut acrylic with a laser?" Yes! Laser cutting acrylic involves the use of a high-powered laser beam that is focused onto the acrylic's surface. The intense heat generated by the laser beam causes the acrylic to melt and vaporize along the path of the beam, resulting in a clean and precise cut.

Since the laser beam is controlled by computer software, even intricate and complex designs can be cut with high accuracy. Compared to other acrylic cutting methods, this method produces smooth edges and minimal kerf width, making it perfect for intricate patterns and shapes.

2. Acrylic Laser Cutting Machine:

To laser cut acrylic, you'll require a laser cutter, which is crucial for streamlining the cutting process and achieving precise results. With various laser cutting machines on the market, many may ask: "Which laser is best for acrylic laser cutting?" or "What machine do I need to cut acrylic?"

Actually, a diode laser cutter is well suited for home and small-scale acrylic laser cutting. So if you want portability, convenience and cost-effectiveness in acrylic cutting, a diode laser cutter is a better option.

3. What is the Minimum Laser Power to Cut Acrylic?

To cut acrylic with lase, questions like "Can a 20W diode laser cut acrylic?" or "Can a 5W diode laser cut acrylic?" are common. However, the necessary laser power depends on factors like acrylic thickness, desired cutting speed, and laser type.

For a diode laser cutter, a minimum power of 10W is recommended. If thicker acrylic poses challenges, adjusting for multiple passes can help overcome this issue.

🔥 Case Study: Laser Cut Acrylic Sheet Within 5 Steps

Preparation checklist for laser cutting acrylic sheet:

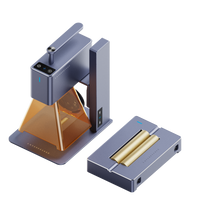

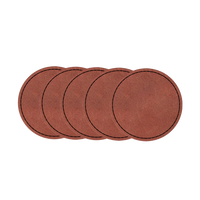

- Cutting Material: 3mm Acrylic Sheet

- Cutting Machine: Laser Cutter

- Cutting Design: Designs, letters, shapes, etc.

Can you laser cut acrylic sheet? Yes! The process is straightforward. So, How long does it take to cut an acrylic sheet? Don't worry, just follow these 5 simple steps to get your laser cut acrylic crafts in a few minutes!

* Before laser cutting acrylic, you might want to add patterns or designs to the acrylic sheet or incorporate construction lines for precise cutting. In such cases, laser cutting the acrylic sheet beforehand can be beneficial.

Step 1: Choose Your Material - 3mm Acrylic Sheet

Selecting the right material is crucial for the laser cut acrylic sheet. Different materials require specific laser settings to ensure precise cutting. In addition, it's important to choose laser-safe acrylic to avoid any potential safety hazards.

In this guide, we'll use a case study to cut acrylic sheets! and craft a acrylic ruler!

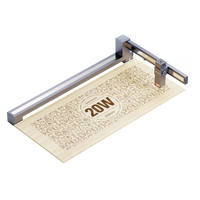

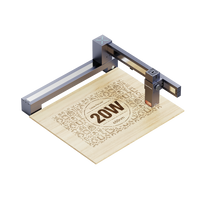

Step 2: Choose the Right Laser Cutting Machine for Acrylic Sheet Cutting

Ensure that your laser cutting machine is compatible with acrylic sheet. Evaluate various usage scenarios and select the most appropriate machine accordingly.

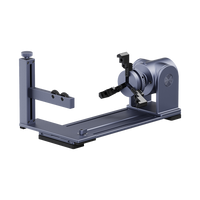

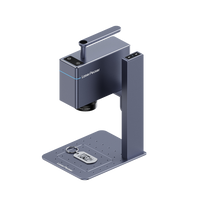

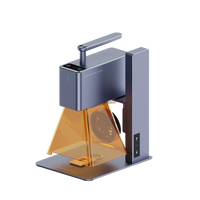

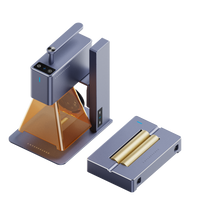

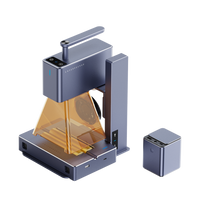

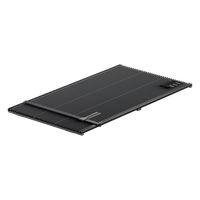

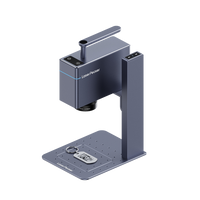

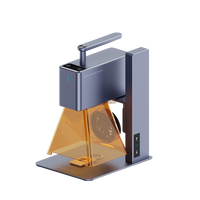

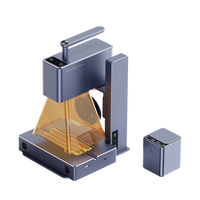

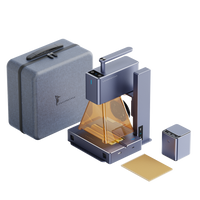

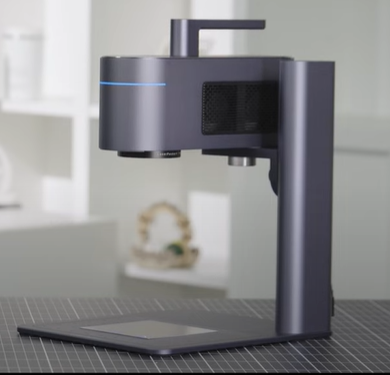

Here, we recommend LaserPecker 4 (LP4), which is a dual-laser and multi-functional laser cutter and engraver. This careful selection will ensure optimal results for your acrylic laser cutting projects.

LaserPecker 4 (LP4) - A Good Cutter & Engraver for Acrylic

Main Features of LaserPecker 4

- Dual-Laser Capability: The LP4 features dual lasers, providing flexibility to tailor your choices based on scene requirements.

- Enhanced Material Compatibility: LP4 is compatible with a wide range of materials, including cutting acrylic paper, leather, MDF and engraving titanium, silver, gold, copper, brass, silicone, rubber, crystal, stone, wood, plastic, leather, etc.

- Improved Resolution: With selectable resolutions ranging from 1k to 8k, the LP4 provides increased flexibility, allowing users to choose the level of detail that best suits their needs.

- High Engraving/Cutting Accuracy & Speed: The LP4 exhibits high engraving/cutting accuracy and speed, achieving precision levels up to 0.003 mm and speeds reaching up to 2000 mm/s.

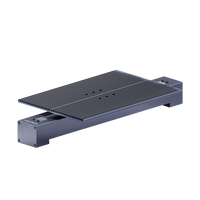

- Expanded Workspace: The LP4 provides an expanded workspace of up to 160 mm x 120 mm, enabling cutting on larger objects.

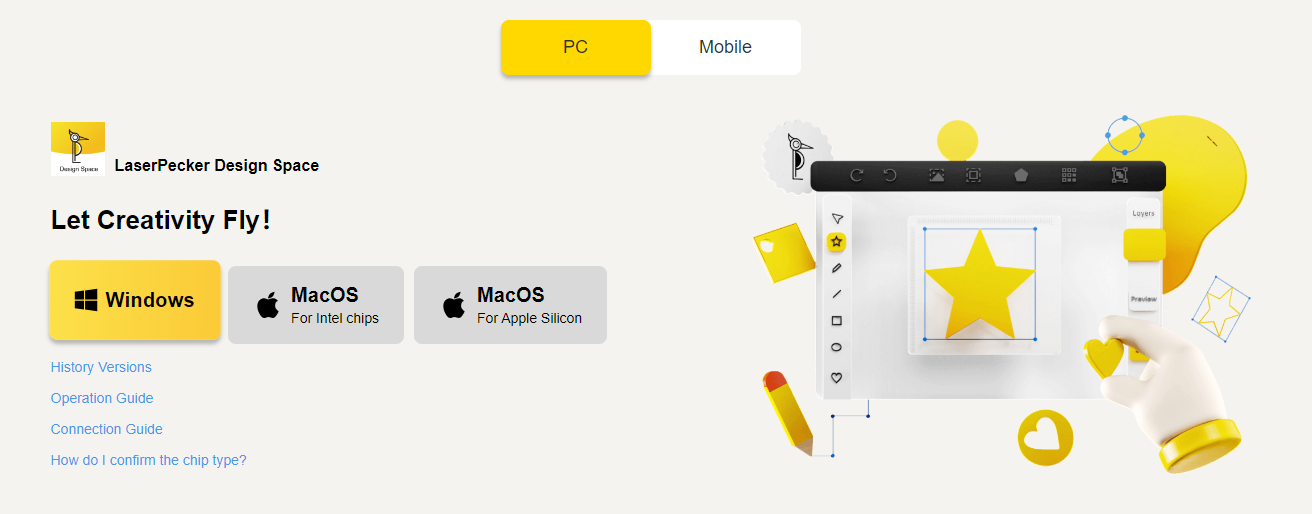

Step 3: Prepare Your Cutting Design

Use graphic design app/software to create or import the shape or design you want to cut on the acrylic sheet's surface. Consider size, shape, and other details.

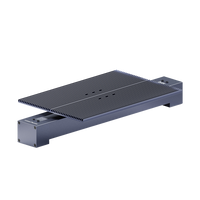

Step 4: Set up the Acrylic Laser Cutting Machine

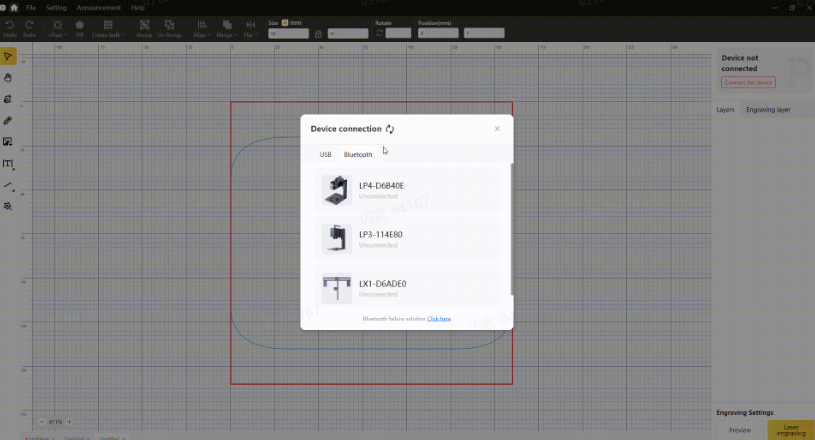

Firstly, Make sure your cutter is powered on, and then connect your laser cutter to your computer or mobile device using the appropriate interface (USB, Bluetooth, etc.)

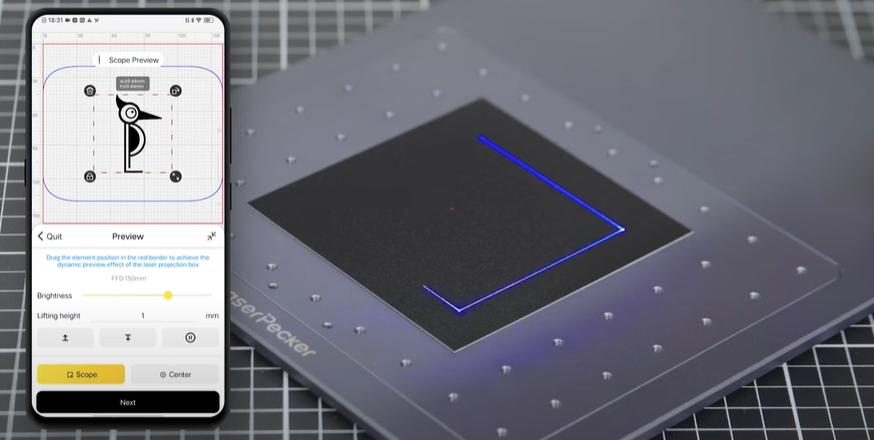

Secondly, Open the graphic design app/software and load your design.

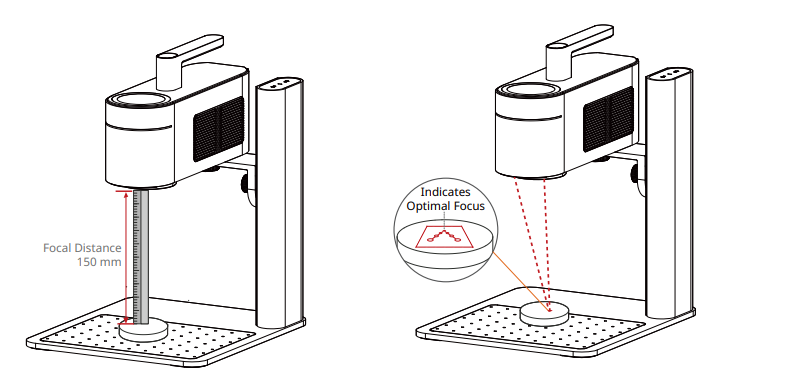

Thirdly, Turn on the "Preview Mode" to confirm if the laser lens is correctly focused. To verify it, you have 2 methods.

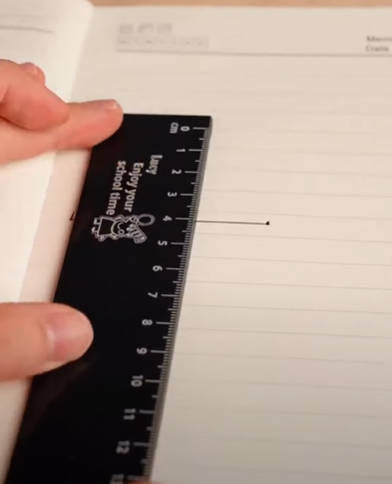

If you choose LaserPecker 4 (LP4), the first method is to use a ruler to measure the distance between the acrylic's surface and the machine, with a recommended distance of 15cm or 150mm.

Alternatively, you can achieve the correct focal length by judging whether the two red dots emitted by the machine overlap. This ensures precise focusing for optimal cutting & engraving results.

Fourthly, You need to place the items within the designated working area and examine the design's appearance on the acrylic sheet. If it doesn't fit correctly, you'll need to adjust its position and size to ensure it aligns with the dimensions of your project.

Finally, Access the software's laser settings to adjust parameters like power, speed, and resolution according to the acrylic sheet's properties and design intricacy. You might be wondering, "How much laser power is needed to cut acrylic?" Rest assured, I've got you covered!

To get the best result, the recommended laserpecker 4 material settings for cutting acrylic sheet is 10 W 450 nm; Resolution: 1k; Power: 100%; Depth: 95%; Pass: 1

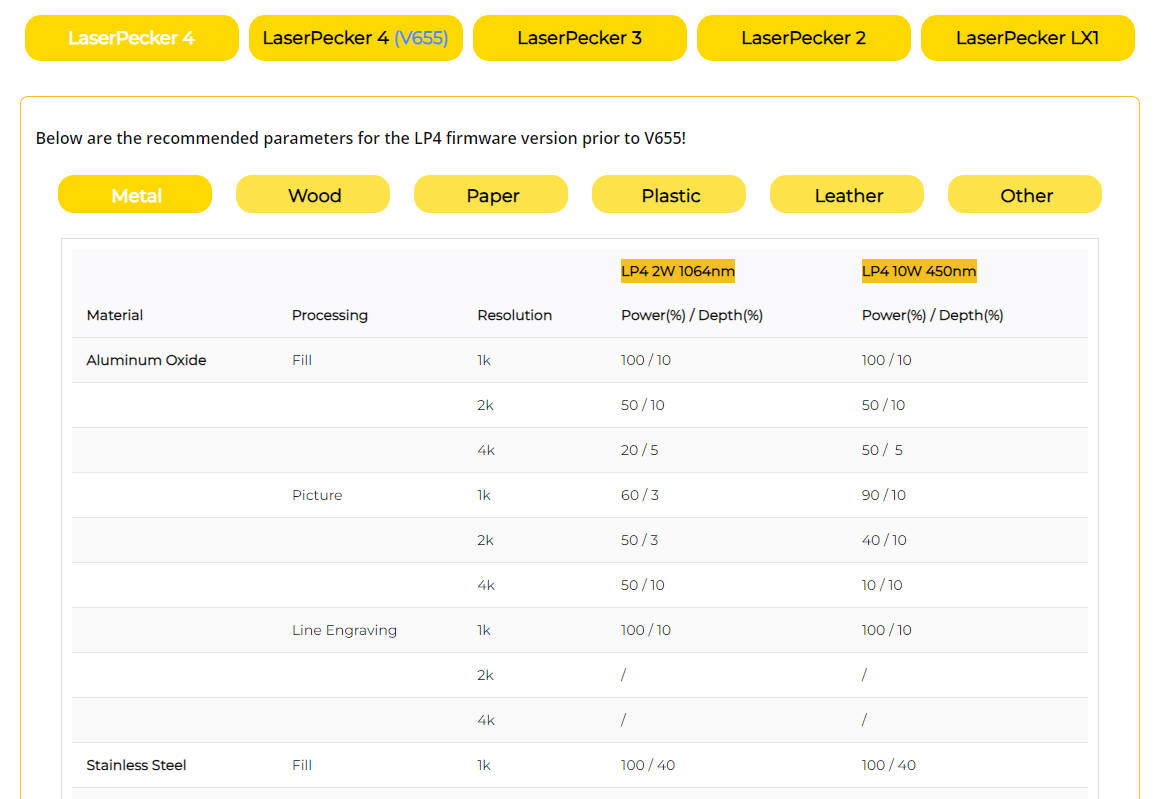

To explore other recommended laserpecker engraving and cutting parameters, refer to the settings table that applies to any laserpecker machines, including LP1, LP2, LP3, LP4 and LX1.

Step 5: Start Cutting Your Acrylic With Laser Now

Double-check everything to avoid mistakes. Then, hit the start button and watch the magic happen. The laser brings your design to life. Keep an eye on it, and you're all set!

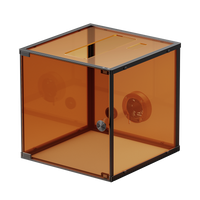

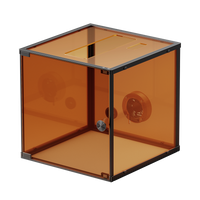

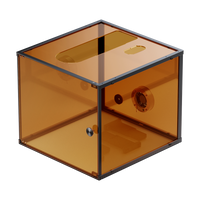

When operating a laser engraving and cutting machine with a 450 nm blue laser, it's advisable to wear goggles or use a laser protection cover to protect your eyes and body from potential harm, as the blue laser can pose risks.

Additionally, please be mindful that smoke may be emitted during the acrylic laser engraving process. Wearing a mask or employing an air purifier is essential for safety.

If you want to know more about how to use the LaserPecker LP4 machine, check out the LP4 User Manual on our website!

Conclusion

In summary, acrylic laser cutting offers versatility and precision, transforming acrylic sheets into intricate designs and functional products with clean edges and intricate patterns. It opens up endless possibilities for artistic expression, industrial manufacturing and personal projects.