The emergence of the compact laser engraver has transformed traditional engraving and cutting industries by providing a portable and space-saving solution. Consequently, it has become increasingly popular in various industries, including automotive, aerospace, and electronics. In contrast to traditional engraving machines, compact engraving machines are small, lightweight, and designed to fit into tight spaces, making them ideal for small workplaces or personal spaces.

This blog aims to explore the latest trends in laser engravers and cutters, as well as the innovative features and breakthroughs of LaserPecker’s compact laser engraving machines. With this comprehensive guide, you will undoubtedly find the perfect compact laser engraving machine for your needs.

Ⅰ. Mainstream Trends for Laser Engravers and Cutters

With the ever-increasing demand for precision in laser engraving and cutting applications, it's thrilling to see advancements in laser technology that can meet these growing needs. No doubt, laser engraving and cutting machines are emerging to cater to these demands as users seek new and innovative ways to apply this technology. There are now even higher expectations for continued improvements in laser technology that will undoubtedly bring even greater advancements in the future. For instance, the LaserPecker3, one of our top-of-the-line machines, can achieve ultra-high precision with 4k precision, which enables it to perfectly reproduce any picture to create a one-of-a-kind masterpiece.

Portability is another important trend. As previously mentioned, compact laser engraving and cutting machines are often lightweight and small yet offer a full range of features. They are capable of engraving on a wide range of materials, including paper, cardboard, ceramic, leather, and many more. With these machines, you can easily personalize items with photos, names, intricate designs, or any other creative idea anywhere you go, even on the street. We don’t need to worry about the weight or the size anymore. The concern about the weight and size of the machine is no longer an issue, so you can comfortably carry it with you and share your personalized engravings with friends and family.

Not to mention, it focuses on the move towards automation. With the use of automatic systems such as the optical path adjustment systems, these machines can now achieve more efficient production without the need for manual intervention. As a result, you can simply upload your preferred image to the software, preview the effect, and choose the necessary parameters to produce the work. It really couldn't get any easier than this!

So, if you're looking to invest in a laser engraving and cutting machine, keep an eye out for machines with precision, automated and versatile capabilities that allow you to work with a variety of materials. With these machines, you can enjoy greater precision, efficiency, and productivity, while unlocking endless creative possibilities.

II. Brief Introduction to LaserPecker's Compact Engraving Machines

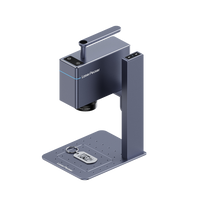

Innovative breakthroughs in technology

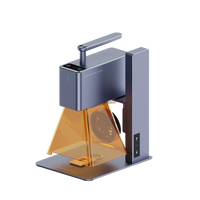

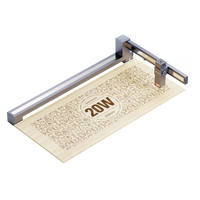

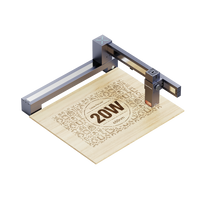

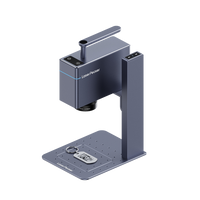

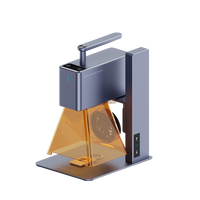

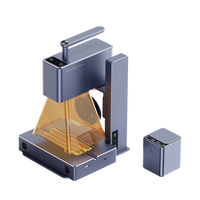

Here we would like to introduce our LaserPecker’s LP2 & LP3 .Compact laser engraving machines are innovative devices that are smaller, more versatile, and more adaptable than traditional large laser equipment. LaserPecker, a leader in this field, stays abreast of the latest technological trends and makes impressive advancements. With features like galvanometer technology, LaserPecker offers numerous benefits that other competitive machines cannot match, including super-fast engraving speeds (48,000mm/min), 0.01mm high-precision (up to 4k), and a variety of versatile accessories and modes to meet users’ diverse needs.

Major characteristics of our LaserPecker products

-

Handheld & Portable: Compact laser engraving machines are often small, lightweight, and feature a compact design, making them ideal for use in small workplaces or personal spaces with limited space. LaserPecker 2 & 3, handheld and portable models, enable you to achieve perfect engravings from any angle by adjusting the laser head’s angle. Equipped with a rechargeable power bank, they can be used for outdoor activities, allowing you to engrave anytime, anywhere.

-

Beginner-friendly: Compact laser engraving machines are equipped with user-friendly interfaces and easy-to-follow instructions, making them ideal for beginners and enthusiasts alike. For example, with the help of Dual Red-light Focus mode, let’s say goodbye to complex manual measurement. Not surprisingly, these machines can be easily operated and controlled through bluetooth connectivity to a computer or mobile phone. Simply download the easy-to-use and powerful LaserPecker App to get started.

-

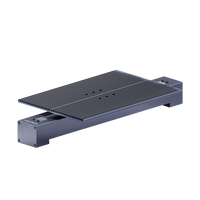

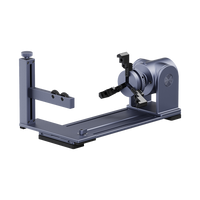

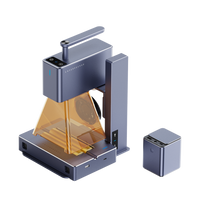

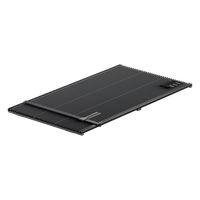

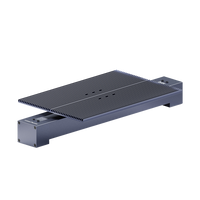

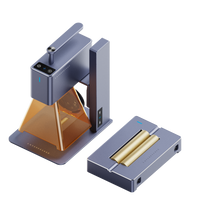

Multi-function: LaserPecker offers three professional modes: Cylinder mode, Slab mode, and Trolley mode, providing users with versatile options to suit different engraving needs. Cylinder mode is designed for 360° rotating engravings on cylindrical objects, as well as curved or uneven surfaces. Slab mode, on the other hand, is ideal for larger flat objects, allowing users to move the plate forward for engraving. Trolley mode offers a larger engraving size of up to 100*2,000 mm, making it perfect for producing large workpieces such as skateboards and wooden doors. LaserPecker 3 also includes adjustable positioning fixtures to achieve batch engraving for increased efficiency

-

High precision and high efficiency: Our compact laser engraving machines use compressed laser spots (as tiny as 0.01mm) to achieve high precision, resulting in a finished product that is an exact match for the software design. Additionally, the integrated design and Galvanometer technology allow for a maximum speed of 800mm/s. With lower energy consumption, the LaserPecker 3 has a working time of up to 240 hours and a lifespan exceeding 10,000 hours.

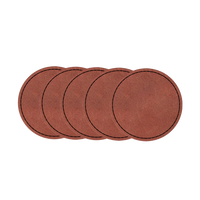

- Wide applicable materials: Our two most popular models offer versatile capabilities for a wide range of materials, but each one is designed to excel in specific applications. The LaserPecker 2 can engrave an extensive list of materials, including painted metal, anodized metal, 304 stainless steel, bamboo, wood, leather, food, paper, cloth, photosensitive stamp, plastic, acrylic, colored glass, glazed ceramics, and more. In contrast, the LaserPecker 3 is specifically optimized for metal, plastic, and leather engraving and is a preferred choice among many jewelry stores. If you’re curious about the differences between these models, we invite you to check out our article: “LaserPecker 2 vs LaserPecker 3: What’s the Difference?”.

-

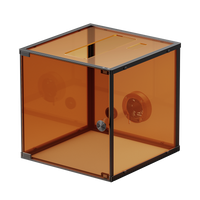

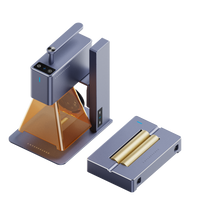

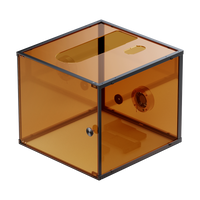

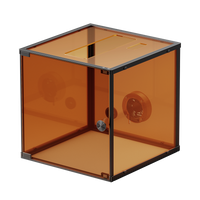

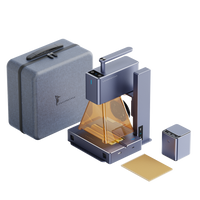

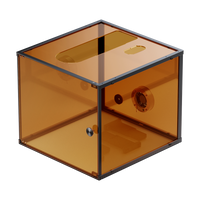

Safety & maintenance: The Basic package includes a protective shield and goggles for safety purposes, while the dust filter at the machine’s back can be removed for easy cleaning. Performing regular maintenance can prevent failures and extend the engraving machine’s lifespan.

In summary, the LaserPecker laser engraving machine caters to a diverse range of users, including both individuals and entrepreneurs. Its small size, flexibility, ease of use, efficient operation, high-quality features, and affordable cost make it useful for various engraving creations and processing fields. The laser engraving machines from LaserPecker are a reliable choice for those seeking both precision and efficiency in their work.

3 comments

kenny lee comment.created_at: comment.updated_at:

Hey Hi,

Would to find more info on your laserPecker portable hand help engraver ?

The engraver will be used for mostly for laptop engraving and some metal product or plastic.

Can it be used to engraver on power coated material ?

Can it be ship to Singapore ?

Thanks

Kenny lee

Feridun nevzat unan comment.created_at: comment.updated_at:

Will it be necessary to buy a laser cutting and engraving head or other parts after purchase? Is there a part that has a certain life and needs to be replaced after a certain number of hours or hours of use?

Soowon Cho comment.created_at: comment.updated_at:

What is the adaptor, which is for certain languages only, and not including Korean? Is it different from the available system language, which includes Korean?