Laser cutting foam has emerged as a transformative technology, offering unparalleled precision and versatility in crafting intricate designs across various industries. From packaging solutions to artistic creations, the ability to shape foam with laser precision has opened new frontiers in customization and efficiency.

This innovative process has found its way into DIY projects, prototyping, and large-scale production, revolutionizing the way foam materials are utilized. In this dynamic landscape, numerous questions arise about the capabilities, safety measures, and creative possibilities associated with laser cut foam. Let's delve into some frequently asked questions to demystify the world of laser-cut foam.

In this article:

Part 1: Types of Foam That Can Be Laser Cut

Laser cutting is a versatile technology that can be used on various materials, including foam. Different types of foam can be laser cut, but it's important to note that not all foams are suitable for laser cutting. The suitability of a foam for laser cutting depends on factors such as the foam's composition, density, and thickness. Here are some common types of foam that are often laser cut:

1. Polyurethane Foam (PU):

Polyurethane foam is a popular choice for laser cutting. It comes in various densities and can be found in both open-cell and closed-cell forms. PU foam is commonly used for packaging, cushioning, and insulation.

2. Polyethylene Foam (PE):

Polyethylene foam is a lightweight and durable foam material. It is often used for packaging, shock absorption, and insulation. Polyethylene foam is available in different colors and densities.

3. Polypropylene Foam (PP):

Polypropylene foam is known for its lightweight and moisture-resistant properties. It is commonly used for packaging, automotive components, and insulation.

4. Polystyrene Foam (PS):

Polystyrene foam is a rigid and brittle foam often used for insulation and packaging. It comes in both expanded (EPS) and extruded (XPS) forms. EPS is more commonly laser cut due to its lower melting point.

5. EVA Foam:

Ethylene-vinyl acetate (EVA) foam is a soft and flexible foam material. It is often used in crafting, cosplay, and for making shoe insoles. EVA foam is available in different thicknesses and colors.

6. Neoprene Foam:

Neoprene foam, also known as polychloroprene, is a flexible and water-resistant foam material. It is commonly used for gaskets, seals, and in aquatic applications.

7. Acoustic Foam:

Acoustic foam is designed to absorb sound and reduce noise. It is commonly used in recording studios, home theaters, and other acoustic applications.

Part 2: How to Laser Cut Foam at Home?

Laser cutting foam at home can be a creative and rewarding DIY project. Here's a general guide on how to laser cut foam at home:

Materials Needed:

- Foam Sheet: Choose the type of foam suitable for laser cutting, such as polyurethane foam, polyethylene foam, or EVA foam.

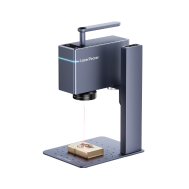

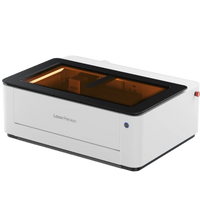

- Laser Cutter: If you don't have a laser cutter, you may consider using a foam laser cutter like LaserPecker LX2 .

- Design Software: Create or obtain a vector design of the shapes you want to cut. You can use LaserPecker Design Space.

Steps:

Step 1 - Prepare the Design:

Use vector design software to create or import the design you want to cut. Ensure that the lines are set to the appropriate cutting settings.

Step 2 - Choose Laser Cutter Settings:

Consult the specifications of your laser cutter and the recommended settings for the type and thickness of foam you are using.

Common settings include laser power, speed, and focal length. These settings may vary depending on the specific laser cutter and foam material.

Step 3 - Secure the Foam:

Place the foam sheet on the bed of the laser cutter. Ensure it is flat and securely positioned to prevent movement during cutting. You may use masking tape or other methods to secure the foam.

Step 4 - Calibrate the Laser Cutter:

Before cutting your actual design, perform a test cut on a small piece of foam to ensure the laser cutter is properly calibrated. Adjust settings as needed.

Step 5 - Load the Design into the Laser Cutter:

Load your design file into the laser cutter's software. Arrange multiple copies of your design if needed.

Step 6 - Run a Test Cut:

Before cutting the full design, run a test cut to confirm that the settings are appropriate. Check the depth and cleanliness of the cut.

Step 7 - Start the Cutting Process:

Once satisfied with the test cut, initiate the cutting process for your full design. Monitor the laser cutter during the process to ensure everything is going smoothly.

Step 8 - Post-Processing:

After the laser cutting is complete, carefully remove the cut foam pieces from the laser cutter bed. Be cautious as the foam may be hot.

Remove any residue or debris from the cut edges.

Step 9 - Clean and Maintain the Laser Cutter:

Clean the laser cutter's lens and bed regularly to maintain optimal performance.

Follow the manufacturer's guidelines for maintenance and safety procedures.

Important Tips:

- Ventilation: Ensure proper ventilation, especially when cutting foam, as it may produce fumes.

- Safety Gear: Wear appropriate safety gear, including safety glasses, when operating the laser cutter.

- Experiment and Adjust: It may take some experimentation to find the optimal settings for your specific foam and laser cutter.

Part 3: Frequently Asked Questions about Laser Cut Foam

1. Can any type of foam be laser cut?

While many types of foam can be laser cut, not all foams are suitable. Common types include polyurethane foam, polyethylene foam, EVA foam, and others. The suitability depends on the foam's composition and density.

2. What thickness of foam can be laser cut?

Laser cutters can handle a range of foam thicknesses, but the specific capabilities depend on the power of the laser cutter. Generally, foam up to several inches thick can be laser cut.

3. Are there safety concerns when laser cutting foam?

Yes, safety is crucial when laser cutting foam. The process may produce fumes, so proper ventilation is essential. Additionally, operators should wear appropriate safety gear, including safety glasses, to protect against laser exposure.

4. Can intricate designs be laser cut on foam?

Yes, laser cutting is ideal for intricate and detailed designs. The precision of the laser allows for the creation of complex shapes, fine details, and intricate patterns on foam surfaces.

5. What file formats are compatible with laser cutting software?

Laser cutting software typically accepts vector file formats such as SVG, DXF, or AI. These formats allow the laser cutter to follow precise paths defined in the design.

6. Can foam with adhesive backing be laser cut?

While it's possible to laser cut foam with adhesive backing, it's essential to consider the adhesive's composition. Some adhesives may release harmful fumes when exposed to the laser, so it's important to choose a foam product compatible with laser cutting.

7. Are there limitations on the size of foam that can be laser cut?

The size of foam that can be laser cut depends on the size of the laser cutter's bed. Larger laser cutters can accommodate bigger foam sheets, but the specific limitations vary between machines.

8. What settings should be used for laser cutting foam?

Laser cutting settings depend on the type and thickness of the foam as well as the specific laser cutter. Common settings include laser power, cutting speed, and focal length. Consult the laser cutter's manual and conduct test cuts to determine the optimal settings.

9. Can laser-cut foam be used for outdoor applications?

The suitability of laser-cut foam for outdoor applications depends on the type of foam used. Some foams may be more resistant to environmental factors, such as moisture and UV exposure, than others.

10. Is laser-cut foam suitable for creating prototypes?

Yes, laser-cut foam is commonly used for creating prototypes in various industries. Its precision and ability to quickly iterate designs make it a valuable tool for prototyping.

11. Can laser-cut foam be painted or coated?

Yes, laser-cut foam can be painted or coated with various finishes. However, it's important to choose paints or coatings suitable for the specific foam material and intended application.

Final Thoughts

As we navigate the frequently asked questions surrounding laser-cut foam, it becomes evident that this technology holds a multitude of advantages, from delivering precise cuts and intricate designs to offering customization and consistency. The safety considerations underscore the importance of responsible operation, ensuring that the benefits of laser-cut foam are enjoyed without compromising the well-being of individuals or the quality of the end product.

As technology continues to evolve, the applications and creative potential of laser-cut foam are likely to expand further, inspiring new innovations and pushing the boundaries of what is achievable in the world of foam fabrication. Whether it's for packaging solutions, artistic endeavors, or functional prototypes, laser-cut foam stands as a testament to the synergy between technology and creativity, offering a pathway to precision in an ever-expanding array of applications.