Laser cutting has become a versatile and popular method for precision crafting, and vinyl materials are no exception to the possibilities offered by this technology. Whether you're a hobbyist creating intricate designs or a professional in the signage and crafting industry, laser cutting vinyl can open up new avenues for creativity.

In this guide, we address common questions and provide a step-by-step overview, ensuring you have the knowledge to select the right materials, choose an appropriate laser cutter, and safely navigate the laser cutting process for vinyl. From understanding the different types of lasers to addressing safety concerns and exploring creative possibilities, this comprehensive guide aims to equip you with the information needed for successful and safe laser cutting vinyl.

In this article:

Part 1: Can You Laser Cut Vinyl? Is it Safe?

Yes, laser cutting vinyl is possible, but it's important to consider some factors to ensure safety and successful results. Vinyl is a thermoplastic material, and when exposed to high temperatures, it can release chlorine gas, which is harmful. Here are some guidelines to follow when laser cutting vinyl:

- Ventilation:Ensure proper ventilation in the laser cutting area to help dissipate any fumes generated during the process. A well-ventilated space or a fume extraction system can help minimize the risk of inhaling harmful gases.

- Material:Verify that the specific type of vinyl you are using is suitable for laser cutting. Some vinyl materials may contain additives or coatings that can produce noxious fumes when exposed to a laser.

- Prevent Overheating:Adjust the laser cutter's power and speed settings withoutexcessive heat buildup. Applying masking tape to the surface of the vinyl can also help prevent charring and provide better cutting results.

- Safety Precautions:Always follow safety guidelines provided by the laser cutter manufacturer. Use appropriate personal protective equipment, such as safety glasses, to protect your eyes from laser radiation.Having a fire extinguisher nearby is also a good safety practice.

Part 2: Select Laser-Safe Vinyl Material

When selecting a vinyl material for laser cutting, it's crucial to choose one that is specifically designed and labeled as "laser-safe" or "laser-compatible". Not all vinyl materials are suitable for laser cutting due to the potential release of harmful fumes or damage to the laser cutter.

Here are some types of vinyl that are commonly considered safe for laser cutting:

1. Polyvinyl Chloride (PVC) Vinyl:

PVC vinyl is often used in the sign-making industry and is generally suitable for laser cutting. However, it's essential to choose PVC vinyl without harmful additives or coatings.

2. Polyurethane (PU) Vinyl:

PU vinyl is another type of vinyl that is often used for heat transfer applications. Some PU vinyl varieties are suitable for laser cutting, but it's important to check with the manufacturer to ensure laser compatibility.

3. Polyethylene (PE) Vinyl:

Polyethylene-based vinyl materials are generally safe for laser cutting. They are commonly used for stencils and other applications.

4. Vinyl with Laser-Compatible Coatings:

Some vinyl materials are specifically coated or treated to make them more compatible with laser cutting. These coatings can help reduce the release of harmful fumes and improve cutting precision.

When searching for laser-safe vinyl, consider purchasing from reputable suppliers or manufacturers that provide detailed information about the material's composition and suitability for laser cutting. Always check the product specifications and documentation to ensure that the vinyl meets safety standards for laser processing.

Part 3: Choose Right Laser Cutter for Vinyl Material

When choosing a laser cutter for vinyl, each type of lasers has its characteristics, advantages, and limitations. Here's some information to help you choose the right laser cutter for vinyl:

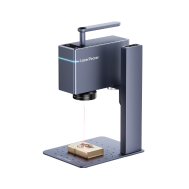

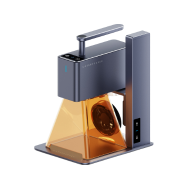

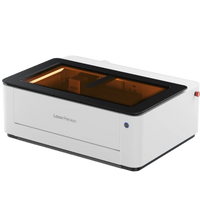

Diode Lasers:

- Power and Precision: Diode lasers are generally lower in power compared to CO2 lasers. They are suitable for engraving and cutting thinner materials but may struggle with thicker materials.

- Materials: Diode lasers are often used for engraving and cutting thin materials like vinyl, paper, leather, and some plastics.

- Ventilation: While ventilation is still important, diode lasers may produce fewer fumes compared to CO2 lasers, depending on the material being processed.

- Size: Diode laser cutters are often more compact and suitable for smaller-scale projects. They are commonly found in desktop or hobbyist machines.

Part 4: How to Laser Cut Vinyl - Step by Step Guide

Here's a step-by-step guide on how to laser cut vinyl using a laser cutter. Please note that safety should always be a top priority, and it's crucial to follow the specific guidelines provided by your laser cutter manufacturer and the vinyl material supplier:

Step 1 - Select Laser-Safe Vinyl:

Choose a vinyl material labeled as "laser-safe" or "laser-compatible." Ensure that the material is free from harmful additives or coatings that could release toxic fumes during cutting.

Step 2 - Prepare Vector Design:

Use vector graphics software like Adobe Illustrator or Inkscape to create or obtain the design you want to cut. Convert the design to vector format (.ai, .svg, .dxf) for compatibility with the laser cutter.

Step 3 - Configure Vector Settings:

Set up your vector design with the appropriate cutting parameters. Define cutting lines, speed, and power settings based on the specifications of your laser cutter and the vinyl material. Consult the laser cutter manual for recommended settings.

Step 4 - Calibrate the Laser Cutter:

Before cutting the actual vinyl, perform test cuts on a small piece to ensure the laser cutter is calibrated correctly. Adjust the power and speed settings until you achieve clean and precise cuts.

Step 5 - Prepare the Vinyl Sheet:

Place the vinyl sheet on the laser cutter bed. If the vinyl has a protective layer or backing, make sure it is facing down, and the cutting side is facing up. Secure the material to the bed to prevent movement during cutting.

Step 6 - Ventilation:

Ensure proper ventilation in the cutting area to disperse any fumes generated during the process. If possible, use a fume extraction system to remove harmful gases.

Step 7 - Load Design into Laser Cutter Software:

Load your vector design file into the laser cutter's software. Double-check the settings and make any necessary adjustments. Some laser cutters may have specific software for controlling the machine.

Step 8 - Start the Laser Cutter:

Initiate the cutting process. Monitor the laser cutter closely to ensure the cutting is progressing as expected. If needed, pause or stop the process if any issues arise.

Step 9 - Post-Processing:

Once cutting is complete, carefully remove the cut vinyl from the laser cutter bed. Depending on your design, you may need to weed or remove excess material to reveal the final product.

Step 10 - Clean the Laser Cutter:

After cutting, clean the laser cutter to remove any residue or debris. Regular maintenance helps maintain the machine's performance.

Part 5: Frequently Asked Questions about Laser Cut Vinyl

1. Can I laser cut heat transfer vinyl for garments?

Some types of heat transfer vinyl are suitable for laser cutting, but it's crucial to check with the vinyl manufacturer for compatibility. Laser cutting heat transfer vinyl can provide precise designs for garment decoration.

2. Can I use the leftover vinyl scraps after laser cutting?

Yes, you can often reuse or repurpose leftover vinyl scraps for smaller projects or designs. However, the usability of scraps depends on the size and condition of the pieces.

3. Can I laser cut adhesive-backed vinyl for stickers?

Yes, adhesive-backed vinyl commonly used for stickers can be laser-cut. Ensure that the adhesive side is facing up during cutting, and be cautious of any residue left on the laser cutter bed.

4. Can I cut multiple layers of vinyl at once with a laser cutter?

Cutting multiple layers of vinyl simultaneously can be challenging as it may lead to uneven cuts or incomplete penetration. It's generally recommended to cut one layer at a time for precise results.

5. What thickness of vinyl can be laser cut?

The thickness of vinyl that can be laser-cut depends on the power of the laser cutter. Thinner vinyl sheets, typically up to a few millimeters, are suitable for most laser cutters, while thicker materials may require higher-powered machines.