Laser-cut felt has emerged as a transformative medium, allowing enthusiasts and professionals alike to bring precision and intricacy to their creative pursuits. The marriage of advanced laser-cutting technology with the soft and versatile nature of felt has opened up a realm of possibilities across various domains.

From crafting personalized home decor to engineering precise industrial components, laser cut felt has become a sought-after choice for those seeking both functionality and aesthetic appeal. In this context, exploring the realm of laser-cut felt raises questions and sparks curiosity about its applications, techniques, and safety considerations.

In this article:

Part 1: Types of Felt

Felt is a versatile fabric made by matting, condensing, and pressing fibers together. There are various types of felt, each with its own characteristics and applications. Here are some common types of felt:

1. Wool Felt:

Wool Felt is made from natural wool fibers. It's soft, durable, and provides good insulation. Wool Felt is often used in crafts, clothing, and industrial applications.

2. Synthetic Felt:

Synthetic Felt is made from synthetic fibers like polyester or acrylic. It's generally less expensive than wool felt. It's available in various colors and suitable for a wide range of applications.

3. Needle-Punched Felt:

Needle-Punched Felt is produced by mechanically entangling fibers with barbed needles. It has a dense and firm structure. And it's used in industrial applications, such as filtration and padding.

4. Adhesive-backed Felt:

Adhesive-backed Felt is the felt with an adhesive backing for easy application. It's commonly used for furniture protection, DIY projects, and crafts.

5. Pressed Felt:

Pressed Felt is created by pressing and compacting fibers without weaving. It's often used in industrial applications, such as gaskets and seals.

6. Craft Felt:

Craft Felt is a type of synthetic felt commonly used in crafting. It's available in a variety of colors and easy to cut into shapes for projects.

7. Industrial Felt:

Industrial Felt is a kind of dense and durable felt used in industrial settings. Its applications include machinery insulation, polishing, and vibration dampening.

8. Medical Felt:

Medical Felt is designed for medical applications. It's used in orthopedic braces, padding, and wound care products.

9. Pressed Wool Felt:

Pressed Wool Felt is made by pressing layers of wool fibers. It's dense and often used in precision machinery for lubrication and cushioning.

10. Decorative Felt:

Decorative Felt is designed for decorative purposes. It's available in various colors, patterns, and thicknesses for creative projects.

11. SAE F-1 Felt:

SAE F-1 Felt ia a specific type of industrial felt meeting certain standards (Society of Automotive Engineers specifications). It's used in lubrication applications, such as oil and grease retention.

Part 2: Applications of Laser-cut Felt

Laser-cut felt is a versatile material that finds various applications due to its precision cutting capabilities. Here are some common applications of laser-cut felt:

1. Crafts and DIY Projects:

Laser-cut felt is popular in crafting and DIY projects due to its ability to create intricate and precise designs. It can be used for making decorations, ornaments, and custom designs in various colors.

2. Fashion and Apparel:

Designers use laser-cut felt to create detailed patterns and embellishments for clothing and accessories. It provides a unique and precise finish to garments.

3. Home Decor:

Laser-cut felt is used in home decor items such as decorative wall art, lampshades, and table accessories. It offers a modern and customized look to interior design.

4. Educational Tools:

In educational settings, laser-cut felt can be used to create teaching aids, learning tools, and interactive educational materials.

5. Industrial Gaskets and Seals:

Laser-cut felt is employed in industrial applications to produce gaskets and seals with precise shapes and dimensions. It provides a cost-effective and efficient solution for sealing purposes.

6. Automotive Interiors:

Felt cut with precision by lasers is utilized in automotive interiors for creating custom designs, logos, and decorative elements. It enhances the aesthetic appeal of vehicle interiors.

7. Prototyping and Model Making:

Architects, designers, and engineers use laser-cut felt for prototyping and model making. It enables quick and accurate representation of design concepts.

8. Medical Applications:

Laser-cut felt can be used in medical settings for creating custom padding, wound dressings, and orthopedic supports. It offers a tailored and comfortable solution.

9. Jewelry and Accessories:

Designers often use laser-cut felt to create intricate designs for jewelry and accessories. It allows for detailed and delicate patterns.

10. Industrial Filtration:

In industrial settings, laser-cut felt is used to create precise filters for air and liquid filtration systems. It provides an effective and accurate solution for filtration needs.

11. Automated Production Processes:

Laser cutting is often integrated into automated production lines for efficiency in cutting felt components for various applications.

Part 3: How to Laser Cut Felt at Home?

Laser cutting felt at home can be a rewarding and creative process, but it requires certain equipment and precautions. Here's a general guide on how to laser cut felt at home:

Materials and Equipment:

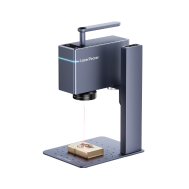

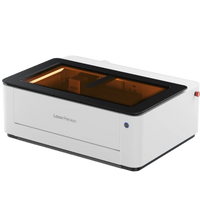

- Laser Cutter:You'll need access to a powerful yet compact laser cutter like LaserPecker LX2.

- Felt Sheet:Choose the type and color of felt suitable for your project. Ensure the thickness is compatible with your laser cutter.

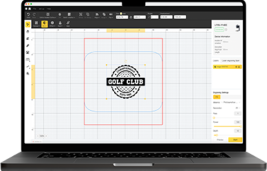

- Vector Design Software:Create or obtain a vector design file of the pattern or shape you want to cut. It's recommended to use LaserPecker Design Space.

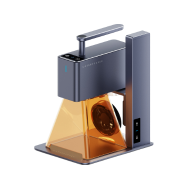

- Ventilation:Make sure you have proper ventilation like LaserPecker Air Purifier to remove any fumes or odors generated during the laser cutting process.

Steps:

Step 1 - Prepare Your Design:

Create or import your design into the vector design software. Ensure that the design is in a format compatible with your laser cutter (common formats include SVG, DXF, or AI).

Step 2 - Set Laser Cutter Parameters:

Consult your laser cutter's manual to determine the optimal settings for cutting felt. Factors to consider include power, speed, and focus. Test the settings on a small piece of felt if needed.

Step 3 - Secure Felt Material:

Place the felt sheet onto the laser cutter bed and secure it in place using masking tape or other suitable methods. Make sure the material lies flat and is smooth to avoid distortions in the cut.

Step 4 - Calibrate and Focus:

Calibrate your laser cutter according to the manufacturer's instructions. Adjust the focus of the laser to the thickness of the felt material.

Step 5 - Load Design into Laser Cutter:

Load your design file into the laser cutter's software. Arrange the design on the felt sheet, ensuring it fits within the cutting area.

Step 6 - Run Test Cuts:

Before cutting your entire design, perform test cuts on a small area to ensure the settings are correct. Make adjustments as needed.

Step 7 - Start Laser Cutting:

Once satisfied with the test cuts, start the laser cutting process. Monitor the machine during the operation to ensure the felt is cutting properly.

Step 8 - Post-Cutting Care:

After the cut is complete, carefully remove the cut pieces from the laser cutter bed. Depending on the design, you may need to do additional steps like removing any remaining ash or residue.

Step 9 - Ventilate the Area:

Ensure proper ventilation in the workspace, especially if the laser cutter generates fumes during the cutting process.

Step 10 - Final Touches:

Depending on your project, you may need to do additional steps like assembling pieces or adding finishing touches.

Part 4: Frequently Asked Questions about Laser Cut Felt

1. What is laser-cut felt?

Laser-cut felt is felt fabric that has been precisely cut using a laser cutter. The laser burns, melts, or vaporizes the material along a specified path, creating detailed and accurate cuts.

2. What types of felt can be laser-cut?

Various types of felt, including wool felt, synthetic felt, and industrial felt, can be laser-cut. The suitability depends on the laser cutter's power and the specific application.

3. Can I laser-cut felt at home?

Yes, it is possible to laser-cut felt at home if you have access to a laser cutter. However, it's essential to follow safety guidelines, use proper ventilation, and ensure the equipment is suitable for the thickness of the felt.

4. What thickness of felt can be laser-cut?

The thickness of felt that can be laser-cut depends on the power and capabilities of the laser cutter. Generally, laser cutters can handle felt sheets ranging from a fraction of a millimeter to several millimeters thick.

5. Can I laser-cut detailed designs on felt?

Yes, laser-cutting is known for its precision, allowing intricate and detailed designs to be cut on felt. The level of detail depends on the resolution of the laser cutter and the quality of the design file.

6. Do I need special software to design for laser cutting?

Vector design software like Adobe Illustrator, CorelDRAW, or free alternatives like Inkscape is commonly used to create designs for laser cutting. These programs allow you to create scalable vector files that are compatible with laser cutter software.

7. How do I clean the edges of laser-cut felt?

Depending on the felt and the laser-cutting process, you may need to clean the edges. Gentle brushing or using a soft cloth can help remove any residual ash or debris. Some materials may benefit from additional cleaning methods.

8. Is laser cutting safe for felt?

Laser cutting is generally safe for felt when proper safety precautions are taken. Ensure proper ventilation, wear appropriate safety gear (such as goggles and gloves), and follow the guidelines provided by the laser cutter manufacturer.

9. Can laser-cut felt be used for wearable items?

Yes, laser-cut felt is commonly used for creating detailed patterns and embellishments in fashion and accessories. The precision of laser cutting allows for intricate designs in wearable items.

10. What are some common applications of laser-cut felt?

Laser-cut felt finds applications in crafts, fashion, home decor, industrial gaskets, prototyping, medical products, and more. Its versatility and precision make it suitable for a wide range of creative and functional projects.

Final Thoughts

In the world of crafting and design, laser-cut felt stands as a testament to the harmonious convergence of tradition and technology. Its ability to render intricate designs with precision has brought about a revolution in various industries, from fashion to industrial manufacturing. As we delve into the world of laser-cut felt, it's essential to tread with a balance of creativity and safety.

Whether you are a DIY enthusiast, a designer pushing the boundaries of fashion, or an engineer optimizing industrial processes, the versatility of laser-cut felt invites innovation and sparks imagination. As we witness the continued evolution of this fascinating fusion of fabric and laser technology, the future holds exciting possibilities for those seeking to shape and redefine the boundaries of what can be achieved through this unique marriage of material and machinery.