Laser cutting has emerged as a versatile and precise method for crafting intricate designs on various materials, including cardboard. This innovative technology allows enthusiasts and creators to transform their ideas into reality with a level of detail that traditional methods might struggle to achieve.

Whether you are a hobbyist exploring the world of laser cutting at home or a professional seeking to add finesse to your projects, understanding the nuances of laser cutting cardboard is essential. In this guide, we delve into the frequently asked questions surrounding the laser cutting of cardboard, providing insights into the materials, techniques, and safety considerations for a successful and rewarding experience.

In this article:

Part 1: Types of Cardboard Used for Laser Cutting

When laser cutting cardboard, it's essential to use materials that are safe and suitable for the process. Cardboard is typically classified into two main types based on its composition:

1. Corrugated Cardboard:

Single-Wall (C-Flute, B-Flute, etc.): This type has a wavy layer between two flat layers. Single-wall corrugated cardboard is commonly used for packaging and is suitable for laser cutting.

Double-Wall (BC-Flute, EB-Flute, etc.): This type has two corrugated layers between three flat layers. It provides added strength and is also suitable for laser cutting.

2. Solid Fiberboard or Chipboard:

Solid Bleached Sulfate (SBS): This is a type of solid fiberboard that consists of multiple layers of bleached chemical pulp. It is often used for higher-end packaging and can be laser cut.

Unbleached Kraft Board: This is another type of solid fiberboard made from unbleached pulp. It is less refined than SBS but is still suitable for laser cutting.

Part 2: How to Laser Cut Cardboard at Home?

Laser cutting cardboard at home can be a creative and rewarding process. Here's a step-by-step guide to help you laser cut cardboard safely:

Materials and Tools:

- Cardboard: Choose the appropriate type of cardboard for laser cutting (corrugated or solid fiberboard).

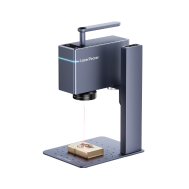

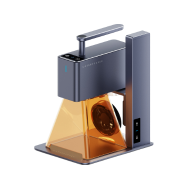

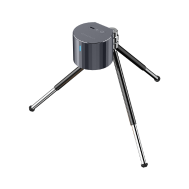

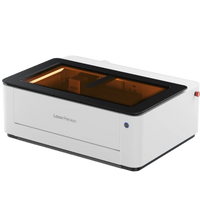

- Laser cutter: You can use a desktop laser cutter, such as a diode laser cutter, that is suitable for cutting cardboard.

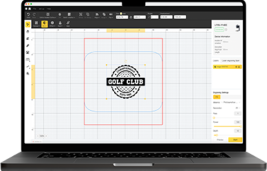

- Design software: Use software like LaserPecker Design Space to create or modify your designs.

- Safety gear: Wear appropriate safety gear, including laser safety glasses, to protect your eyes from laser radiation.

Steps:

Step 1 - Design your project:

Use vector design software to create or download a design for your laser cutter. Ensure that the design fits within the cutting area of your laser cutter.

If you're new to designing, many online platforms offer free or paid vector designs that you can use.

Step 2 - Prepare the cardboard:

Place the cardboard on the laser cutter bed. Ensure it lies flat and is secured to prevent movement during cutting.

If the cardboard has any coatings or adhesives, make sure they are laser-safe, as some materials can release harmful fumes during cutting.

Step 3 - Configure laser settings:

Set the laser cutter parameters such as power, speed, and focus based on the type and thickness of the cardboard. Refer to the laser cutter and cardboard manufacturer's guidelines for recommended settings.

It's recommended to do a test cut on a scrap piece of cardboard to fine-tune the settings.

Step 4 - Import the design:

Load your design into the laser cutter software. Ensure that the design is correctly positioned within the cutting area.

Step 5 - Run a test cut:

Before cutting your final project, run a test cut on a small section of the cardboard to verify that the settings are correct and the design looks as expected.

Step 6 - Start the laser cutting process:

Once satisfied with the test cut, initiate the cutting process for your complete design. Monitor the laser cutter throughout the cutting process to ensure everything is going smoothly.

Step 7 - Remove the cut pieces:

After the laser cutter completes the job, carefully remove the cut pieces from the bed. Be cautious, as edges might be hot immediately after cutting.

Step 8 - Post-processing:

If necessary, remove any residual burnt edges or marks using sandpaper or other suitable methods.

Part 3: Frequently Asked Questions about Laser Cut Cardboard

1. Can any type of cardboard be laser cut?

Not all cardboard is suitable for laser cutting. It's essential to use cardboard without coatings or adhesives that can produce harmful fumes during laser cutting. Corrugated and solid fiberboard types are commonly used.

2. How thick of cardboard can be laser cut?

The thickness of cardboard that can be laser cut depends on the power of the laser cutter. Generally, laser cutters can handle cardboard ranging from a few millimeters to around 1/4 inch (6 mm) thickness.

3. What safety precautions should I take when laser cutting cardboard at home?

Wear laser safety glasses to protect your eyes from laser radiation.

Operate the laser cutter in a well-ventilated area to disperse fumes.

Ensure the cardboard is free from materials that can produce toxic fumes during cutting.

4. Can I use any vector design software for creating designs?

Yes, you can use various vector design software such as Adobe Illustrator, CorelDRAW, or Inkscape to create designs for laser cutting. Ensure the software is compatible with your laser cutter.

5. Do I need to treat the cardboard before laser cutting?

In most cases, untreated cardboard is suitable for laser cutting. However, it's crucial to check if the cardboard has any coatings or adhesives that may produce harmful fumes.

6. How do I determine laser cutter settings for cardboard?

Consult the guidelines provided by the laser cutter and cardboard manufacturers. Conduct test cuts on scrap cardboard to fine-tune settings for power, speed, and focus.

7. Can I engrave on cardboard using a laser cutter?

Yes, laser cutters can be used for engraving on cardboard. Adjust the laser settings to achieve the desired engraving depth.

8. Are there any restrictions on the type of designs that can be laser cut on cardboard?

As long as the design fits within the cutting area of the laser cutter, you can create intricate and detailed designs. However, intricate designs may require more time for cutting.

9. Can I reuse scrap cardboard for laser cutting?

Yes, you can reuse scrap cardboard for test cuts or smaller projects. Ensure the cardboard is flat and free from any debris that could interfere with the laser cutting process.

10. What post-processing steps are recommended after laser cutting cardboard?

Depending on the desired finish, you may need to sand the edges to remove any residual burn marks or sharp edges. Additionally, you can paint or finish the laser-cut cardboard as needed.

Final Thoughts

As we conclude this exploration into the world of laser cutting cardboard, it becomes evident that this technique offers a myriad of possibilities for creativity and precision. The ability to transform flat sheets of cardboard into intricately cut and engraved designs is not only a testament to technological advancements but also an invitation for individuals to express their artistic visions.

However, it is crucial to approach laser cutting with a diligent awareness of safety guidelines, material specifications, and thoughtful design considerations. Whether you are embarking on a small DIY project or engaging in professional endeavors, the fusion of creativity and technology in laser cutting promises a journey of discovery, innovation, and the crafting of tangible dreams.