Laser engraving has revolutionized the art of personalization and identification, offering a precise and efficient method for creating intricate designs on a variety of materials. Among its versatile applications, laser engraving finds a notable place in the customization of keys. Whether for decorative purposes, security measures, or promotional items, laser engraving allows for the creation of unique and enduring marks on key surfaces.

In this guide, we will explore the essential steps and considerations involved in engraving a key, highlighting the tools, materials, and processes that contribute to achieving professional and visually appealing results.

In this article:

Part 1: Engraving Tools for Keys

Engraving tools for keys are essential for creating unique identifiers or personalizing keys for various purposes. Here are some common engraving tools used for keys:

- Rotary Engraving Machine:

Description: Rotary engraving machines use a rotating cutter to engrave on various materials, including metal keys.

Features: They are versatile and can handle different types of key materials.

- Diamond Drag Engraving Tools:

Description: Diamond drag engraving tools use a diamond-tipped stylus to scratch or drag across the key's surface, creating a permanent mark.

Features: Suitable for metal keys, durable and long-lasting.

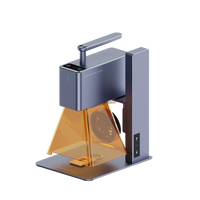

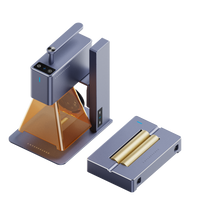

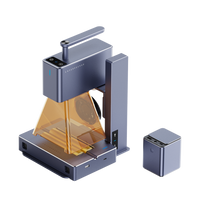

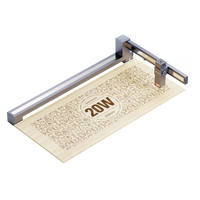

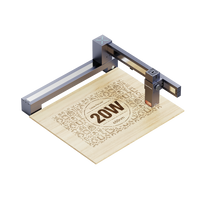

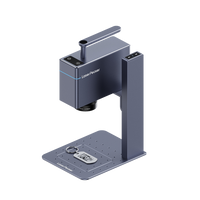

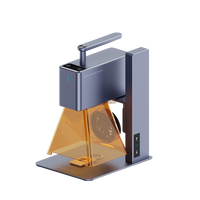

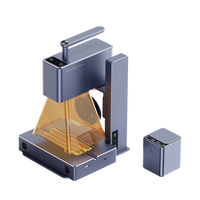

- Laser Engraving Machine:

Description: Laser engraving machines use a laser beam to remove material and create precise and detailed engravings.

Features: Highly accurate, suitable for a variety of materials, and can produce intricate designs.

- Handheld Engraving Tools:

Description: Handheld engraving tools are portable devices that allow for manual engraving on keys.

Features: They provide flexibility and control, often used for simple inscriptions or basic designs.

- Pneumatic Engraving Systems:

Description: Pneumatic engraving tools use air pressure to control the engraving process, offering precision and consistency.

Features: Suitable for high-volume engraving tasks, producing clean and professional results.

- Computerized Engraving Systems:

Description: Computerized engraving systems are integrated with software that allows users to design and program intricate patterns or text.

Features: Ideal for custom designs and mass production, providing efficiency and accuracy.

- Carbide Engraving Bits:

Description: Carbide engraving bits are cutting tools that use carbide tips for precision engraving on various materials.

Features: Durable and capable of producing fine details on keys.

- Electric Engraving Pens:

Description: Electric engraving pens are handheld devices that use a vibrating or reciprocating motion to create markings on keys.

Features: Portable, easy to use, and suitable for basic engraving tasks.

When choosing an engraving tool for keys, consider factors such as the material of the keys, the level of detail required, and the volume of engraving work. Additionally, ensure that the chosen tool meets safety standards and is compatible with the type of key material you'll be working with.

Part 2: How to Laser Engrave A Key?

Laser engraving a key involves using a laser engraving machine to remove material from the key's surface, creating a permanent mark or design. Here's a general guide on how to laser engrave a key:

Materials and Equipment:

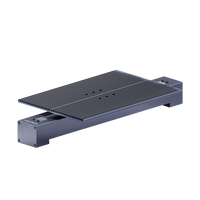

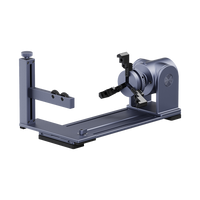

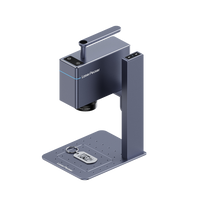

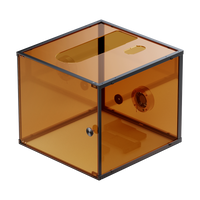

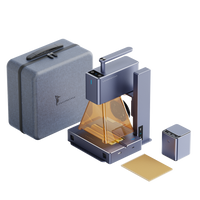

Laser Engraving Machine: Choose a laser engraving machine suitable for the size and type of keys you are working with.

Software: The laser engraving machine is typically controlled by a computer, so you'll need one with the necessary software.

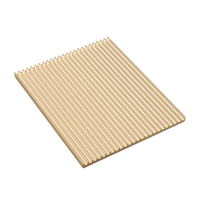

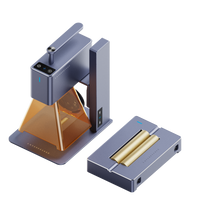

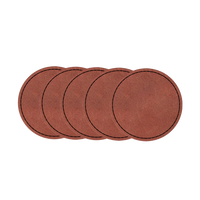

Key Blank: Ensure the key is made of a material suitable for laser engraving, such as metal or certain plastics.

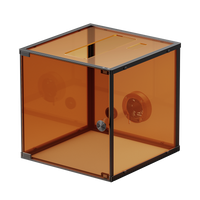

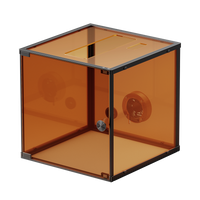

Safety Gear: Wear appropriate safety gear, such as safety glasses, to protect your eyes from the laser.

Steps:

- Prepare the Key:

Clean the key surface to remove any dirt, oil, or debris. A clean surface ensures better engraving results.

If needed, apply a thin layer of masking tape on the key's surface. This can help protect the key from potential discoloration or residue during the engraving process.

- Design Preparation:

Use graphic design software compatible with the laser engraving machine to create or import the design you want to engrave on the key.

Adjust the size, position, and orientation of the design according to your preferences.

- Machine Setup:

Turn on the laser engraving machine and ensure it is properly calibrated.

Load the key onto the engraving bed or platform, securing it in place to prevent movement during engraving.

Adjust the focus of the laser to ensure precise engraving.

- Software Settings:

Open the software connected to the laser engraving machine.

Import the design file and configure the engraving settings, including power, speed, and resolution. The optimal settings depend on the material of the key.

- Test Run:

Before engraving the actual key, perform a test run on a similar material or scrap piece to ensure the settings are correct and the design appears as expected.

- Engraving Process:

Start the laser engraving process. The laser will follow the specified design, removing material and creating the desired markings on the key.

Monitor the process to ensure proper engraving depth and quality.

- Post-Processing:

Once the engraving is complete, carefully remove the key from the machine.

If masking tape was applied, peel it off to reveal the engraved design.

Clean the key to remove any residue from the engraving process.

- Final Inspection:

Inspect the engraved key to ensure the design meets your expectations.

If necessary, use a soft cloth and a mild cleaner to further clean and polish the key.

Conclusion

In conclusion, laser engraving has proven to be a transformative technique in the realm of key customization, offering unparalleled precision and versatility. As we've navigated through the steps outlined in this guide, it becomes evident that laser engraving provides a seamless way to imbue keys with personalization, security features, or branded insignias.

From rotary engraving machines to laser-equipped systems, the array of engraving tools available ensures that one can adapt the process to various key materials and design preferences. As technology continues to advance, the art of laser engraving on keys stands at the intersection of functionality and creativity, providing a lasting imprint that goes beyond mere utility.