Background

The Challenge

-

Quick Turnaround: Consumers entering LAMY stores expect to walk out with a personalized, engraved product. However, traditional engraving machines require the items to be sent to a factory for engraving, resulting in a turnaround time that typically takes a week or even longer.

-

On-site Engraving: The second issue with traditional engraving machines is their size. Their large dimensions require LAMY to allocate dedicated workspace in the store, and it may even necessitate renovations, which is impractical for LAMY.

-

Easy Operation: LAMY aims to control administrative costs by enabling its employees to operate the machine for precise engraving without requiring specialized training.

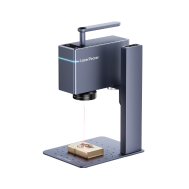

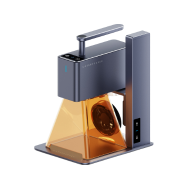

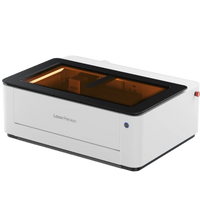

The Solution: LaserPecker LP3

-

High-Speed Engraving: Born for metal engraving. The LaserPecker LP3 offers 1W 1064nm infrared laser. With engraving speed up to 800mm/s. It significantly reduces wait times for customers who want instant personalization., ensuring them a seamless and interactive buying process.

-

Compact Design: Small and portable, The LP3 is 6.64 x 2.44 x 6.67 inch, allowing it to fit seamlessly into LAMY’s retail stores without requiring additional workspace (only need a corner on the front desk).

-

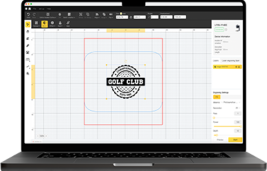

Three-Step Operation: The LP3's intuitive system allows anyone new to the machine to get started easily with just three simple steps, significantly easing the learning curve. This enables LAMY's employees to use the machine without specialized training, thereby reducing administrative costs.