Plywood is often used in our daily life. Laser cutting takes the material plywood to a whole new level, transforming it into a medium for intricate designs. The precision and speed of laser cutters allow craftsmen and manufacturers to achieve levels of detail that were once challenging or impossible with traditional cutting methods.

In this blog, we’ll take a closer look at how to laser cut plywood, exploring the technology behind it, its myriad applications, and the exciting possibilities it brings for the future of woodworking and design.

In this article:

Part 1: What Is Plywood?

Plywood, a versatile engineered wood product, consists of layers (or plies) of wood veneer glued together with grains running perpendicular to each other.

There are two types of plywood. Interior Plywood is suited for applications where exposure to the elements is limited, such as indoor furniture and decorative items. While Exterior Plywood is treated to withstand moisture and weather conditions, ideal for outdoor projects like signage or garden decor.

Plywood Grading is divided into A, B, C, and D Grades. A-grade plywood has fewer imperfections, making it suitable for visible surfaces. Lower grades may have more knots and defects but can be ideal for hidden areas.

Part 2: Types of Plywood Suitable for Laser Cutting

Laser cutting plywood involves precision and control, and the choice of plywood is crucial for achieving optimal results. Different types of plywood offer varying characteristics that can impact the cutting process and the final outcome. Here, we'll explore the key considerations when selecting plywood for laser cutting.

1. Thickness Considerations

Standard Thickness Options:

Common thicknesses range from 1/8 inch to 3/4 inch. Thinner plywood is suitable for intricate designs, while thicker options provide sturdiness for structural applications.

Layer Count and Flexibility:

More layers in plywood contribute to increased flexibility. Thicker plywood with more layers may require adjustments in laser cutting settings to achieve optimal results.

2. Surface Finish and Treatment

Unfinished vs. Finished Plywood:

Unfinished: Allows for customization with paints, stains, or finishes after laser cutting.

Pre-finished: May have a protective coating or finish, reducing the need for post-processing but requiring careful consideration of laser settings.

Adhesive Types:

Different adhesives are used to bind plywood layers. Formaldehyde-free adhesives are preferable for environmentally conscious projects.

Part 3: DIY Guide: How to Laser Cut Plywood at Home?

Laser cutting plywood at home can be a rewarding and creative venture, allowing you to craft intricate designs with precision. Follow this step-by-step guide to safely and effectively laser cut plywood in your own workspace.

Step 1. Equipment and Materials

- Plywood: Select the appropriate plywood type based on your project. Ensure the dimensions fit your laser cutter bed.

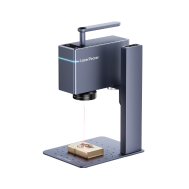

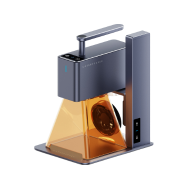

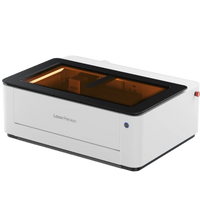

- Laser Cutter: Choose a laser cutter suitable for your workspace and project requirements. Desktop laser cutters like from LaserPecke are ideal for home use.

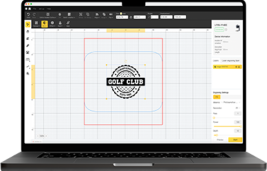

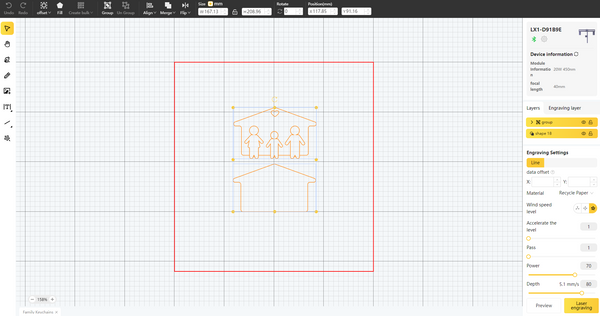

- Design Software: Use a computer to create or upload your design. LaserPecker Design Space software is a good choice for you.

Step 2. Design Preparation

Create or Import Design: Design your project in vector format, ensuring it's compatible with your chosen software.

Set Cutting Parameters: Configure laser settings, specifying power, speed, and frequency based on your plywood type. Refer to your laser cutter and plywood manufacturer's guidelines.

Step 3. Material Preparation

Plywood Inspection: Check the plywood for any defects, and confirm it fits securely on the laser bed.

Securing Plywood: Use clamps or other securing methods to prevent the plywood from moving during cutting.

Step 4. Laser Cutting Process

Ventilation: Ensure proper ventilation in your workspace or use an exhaust system to remove fumes.

Power On: Power up the laser cutter and computer, ensuring all safety features are in place.

Test Cut: Perform a small test cut on scrap plywood to verify settings and make necessary adjustments.

Load Design: Load your design into the laser cutter software and position it on the plywood.

Start Cutting: Initiate the cutting process, monitoring the laser cutter throughout.

Post-Cutting Inspection: Examine the cut edges and overall quality. Make adjustments for subsequent cuts if needed.

For more info about this project, please visit our LaserPecker CraftZone. More interesting projects are waiting for you!

Step 5. Safety Measures

Protective Gear: Wear appropriate safety gear, including laser safety glasses and, if necessary, a mask.

Fire Safety: Have fire safety equipment nearby, and never leave the laser cutter unattended during operation.

Ventilation: Toxic gases may be produced during laser cutting. Please ensure that the working environment is well ventilated.

Workspace Organization: Keep your workspace organized to minimize the risk of accidents.

Part 4: Applications of Laser Cut Plywood

Laser cut plywood finds diverse applications across various industries due to its precision and adaptability. Here are key areas where laser-cut plywood excels:

1. Architectural and Interior Design

Ornamental Screens: Laser-cut plywood is often used to create decorative screens, room dividers, and intricate architectural details.

Custom Furniture Components: Designers utilize laser cutting for crafting custom furniture components with complex patterns and shapes.

2. Furniture Manufacturing

Prototyping: Rapid prototyping with laser-cut plywood allows furniture designers to test and refine designs efficiently.

Inlay and Veneer Detailing: Laser cutting enables precise inlays and veneer detailing, enhancing the aesthetics of wooden furniture.

3. Art and Craft Projects

Wooden Art Pieces: Artists leverage laser-cut plywood to create unique wooden art pieces, incorporating intricate designs and patterns.

Craftsmanship in Models: Model makers use laser-cut plywood for creating detailed architectural models and prototypes.

4. Prototyping and Model Making

Architectural Models: Architects use laser-cut plywood to produce detailed scale models of buildings and structures.

Product Prototypes: Manufacturers employ laser cutting for prototyping components and products with precision.

5. Educational Materials

Educational Kits: Laser-cut plywood is used to create educational kits and learning materials for schools and educational institutions.

STEM Projects: Students engage in STEM (Science, Technology, Engineering, and Mathematics) projects using laser-cut plywood for hands-on learning.

6. Personalized Décor and Accessories

Home Décor Items: Individuals use laser-cut plywood for crafting personalized home décor items, such as wall art, clocks, and lighting fixtures.

Jewelry and Accessories: Designers create intricate jewelry and fashion accessories using laser-cut plywood.

Part 5: FAQs about Laser Cut Plywood

1. Can laser-cut plywood be painted or stained after cutting?

Yes, laser-cut plywood provides a smooth surface that can be easily painted, stained, or finished according to your design preferences after the cutting process.

2. Is laser cutting suitable for mass production?

Yes, laser cutting is widely used in mass production due to its efficiency, precision, and the ability to replicate designs accurately across multiple pieces.

3. Are there limitations to the size of plywood sheets that can be laser-cut?

The size of the laser cutter bed determines the maximum dimensions of plywood sheets that can be accommodated. Ensure your chosen laser cutter can handle the sheet size required for your project.

4. How can I avoid charring on the edges of laser-cut plywood?

Optimize laser settings to find the right balance between power and speed. Testing on a small scrap piece can help determine the optimal settings to minimize charring.

5. Can laser-cut plywood be engraved?

Yes, laser cutters can be used for engraving detailed designs or text onto the surface of plywood, adding personalized and decorative elements to projects.