Engraving ceramic mugs can add a personalized touch and elevate their aesthetic appeal. Whether you're a hobbyist or seeking a unique gift idea, understanding the intricacies of engraving on ceramic surfaces is essential.

This blog aims to provide a comprehensive guide on how to engrave ceramic mugs effectively, offering insights, techniques, and tips for a successful project.

In this article:

Part 1: What Is Laser Engraved Ceramic Mug?

Laser engraving ceramic mugs refers to the art of etching or engraving designs, patterns or text on the surface of ceramic mugs. This process ensures the longevity and durability of the design, making it a first choice for personalized or promotional items. Engraved markers can stand the test of time, provide a lasting impression and withstand frequent use and cleaning.

Laser engraving can etch intricate designs, logos, names or messages onto the surface of your cup. Highly personalizable to suit personal preference, occasion or brand needs.

Part 2: How to Laser Engrave Ceramic Mugs?

Laser engraving is a popular and precise method for decorating ceramic mugs, offering intricate designs and durable results. Here's a step-by-step guide on how to laser engrave ceramic mugs effectively:

Step 1 - Choose the Right Ceramic Mugs:

Select ceramic mugs specifically designed for laser engraving. Ensure they have a smooth, glazed surface that's compatible with the laser engraving process.

Step 2 - Prepare the Artwork:

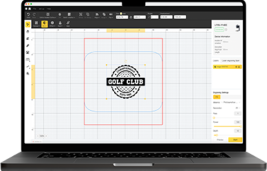

Create or select the design, text, or logo you want to engrave onto the mug using design software. Convert the design into a format compatible with the laser engraving machine.

Step 3 - Set Up the Laser Engraving Machine:

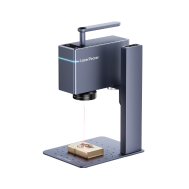

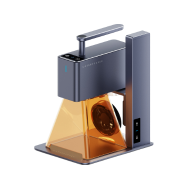

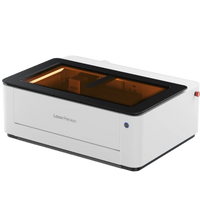

Follow the manufacturer's instructions for setting up the laser engraving machine. Adjust the settings based on the type of ceramic material and the desired depth and clarity of the engraving. Parameters may include laser power, speed, and resolution.

Step 4 - Secure the Mug:

Place the ceramic mug securely within the engraving area of the machine. Ensure it's level and won't move during the engraving process. Some machines may have fixtures or rotary attachments designed for mugs to ensure precise and consistent engraving.

Step 5 - Test Engrave:

Before engraving the final product, perform a test run on a similar ceramic mug to ensure the settings are correct and the design appears as intended. Adjust settings if necessary to achieve the desired result. Remember to wear laser safety glasses before operating the laser engraving machine.

Step 6 - Start Engraving:

Once satisfied with the test engraving, proceed to engrave the actual ceramic mug. Activate the laser engraving machine and allow it to engrave the chosen design onto the mug's surface. Monitor the process to ensure accuracy and quality.

Step 7 - Clean and Inspect:

After engraving, carefully remove the mug from the machine. Clean off any debris or residue left from the engraving process. Inspect the engraved design for quality, making sure it meets your expectations.

Step 8 - Optional Finishing:

Some engravers may opt to apply additional treatments or coatings to enhance the appearance and durability of the engraved design. This could involve sealing the engraving with a ceramic sealant for added protection.

Step 9 - Quality Check and Packaging:

Before finalizing the product, conduct a final quality check to ensure the engraving meets standards. Once satisfied, package the engraved ceramic mug appropriately to prevent any damage during transportation or handling.

If you want to learn more about laser engraved ceramic mug projects, visit our LaserPecker CraftZone!

Here is another video guide on laser engraving ceramic mug (White Color):

Part 3: Alternative 7 Methods to Engrave Ceramic Mugs

Hand Engraving: Hand engraving involves using specialized hand tools like diamond-tipped or carbide engraving pens to etch designs onto ceramic surfaces manually. This method allows for intricate and artistic designs but requires skill and precision.

Chemical Etching: Chemical etching involves using acid or specialized etching solutions to create designs on ceramic surfaces. This method chemically etches away the surface to reveal the engraved design. It requires careful handling of chemicals and precise application techniques.

Stencil and Etching Cream: Create a stencil of the desired design and apply etching cream onto the ceramic mug within the stencil boundaries. The cream reacts with the ceramic surface, creating an etched design. This method is relatively easy and safe to use but might not offer as fine details as other methods.

Electric Engraving Tools:Electric rotary tools equipped with diamond or carbide-tipped bits can be used for engraving ceramic mugs. These tools allow for detailed designs and offer more control than hand engraving. However, they require steady hands and practice for precision.

Sandblasting: Sandblasting involves using a high-pressure stream of abrasive material (such as sand or aluminum oxide) to etch designs onto ceramic surfaces. This method creates a textured, matte finish and is suitable for larger-scale production.

Decal Transfer: Create or purchase decals with the desired design and apply them to the ceramic mug's surface. After application, fire the mug in a kiln or oven at the appropriate temperature to fuse the decal onto the ceramic, creating an engraved appearance.

Engraving Services: Utilize professional engraving services that specialize in ceramic materials. Many companies offer custom engraving options using various techniques, providing a hassle-free solution for personalized ceramic mugs.

Part 4: Hot 10 FAQs About Engraving Ceramic Mugs

Q1: Can all ceramic mugs be engraved?

Not all ceramic mugs are suitable for engraving. Ensure the mugs have a smooth, glazed surface that can withstand the engraving process without chipping or cracking.

Q2: What type of engraving tools are best for ceramic mugs?

Laser engraving machines, diamond-tipped engraving pens, electric rotary tools, and sandblasting equipment are commonly used for engraving ceramic mugs. Choose tools based on the desired level of detail and personal proficiency.

Q3: Can you engrave personalized messages or logos on ceramic mugs?

Yes, engraving allows for customization. You can engrave names, logos, messages, or intricate designs on ceramic mugs, offering a personalized touch.

Q4: What's the best file format for submitting designs for engraving?

File formats like SVG, AI, DXF, and high-resolution image files (JPEG, PNG) are suitable for submitting designs to be engraved. Consult with the engraving service or machine's specifications for preferred formats.

Q5: How deep should the engraving be on ceramic mugs?

The depth of engraving depends on personal preference and the intended durability of the design. Typically, a depth of 0.5mm to 1mm is sufficient for visibility and durability.

Q6: Can I engrave already glazed ceramic mugs?

Engraving on already glazed ceramic mugs is possible but might require specialized equipment or techniques. Sandblasting or using a laser at higher power settings may help engrave on glazed surfaces.

Q7: What's the best way to clean engraved ceramic mugs?

Handwashing with mild soap and a soft sponge is recommended for engraved ceramic mugs. Avoid abrasive cleaners or harsh scrubbing that could damage the engraved design.

Q8: Is it possible to color the engraved design on ceramic mugs?

Yes, after engraving, some techniques involve infilling the engraved design with specialized paint or pigment. Alternatively, ceramic paints may be used before firing the mug to add color to the design.

Q9: Can I engrave ceramic mugs at home or should I seek professional services?

Engraving ceramic mugs at home is possible with the right tools and techniques, but professional services may offer precision and equipment for more intricate designs.

Q10: How do I ensure the longevity of the engraved design on ceramic mugs?

Proper care, avoiding extreme temperatures, and using mild detergents during cleaning can help maintain the engraved design's longevity on ceramic mugs.

Conclusion

All in all, engraving ceramic mugs offer an avenue for creativity and personalization. Whether using laser technology, hand tools or alternative methods, the process allows for intricate designs, logos and messages to decorate ceramic mugs.

By mastering these methods and considering the FAQs, enthusiasts can embark on an engraving journey that adds a unique touch to ceramic mug gifts, merchandise, or personal collections.